Ever tried to fit a standard credit card into a handmade leather wallet only to find it's a hair too tight? It’s frustrating. That tiny gap between "perfect fit" and "useless" often comes down to a fraction of an inch, specifically the leap from imperial to metric. If you’re staring at a ruler or a technical drawing and need to know 3 3/8 in cm, the short answer is 8.5725 cm.

Math is weird. We live in a world where some people think in base-10 and others are stuck visualizing eighths of an inch on a metal tape measure. When you're dealing with 3 3/8 inches, you're not just looking at a number; you're looking at the standard width of a bank card, the common diameter of a recessed lighting fixture, or the width of a "standard" deck of playing cards. These aren't random digits. They are the invisible skeletons of our daily objects.

The Math Behind 3 3/8 in cm

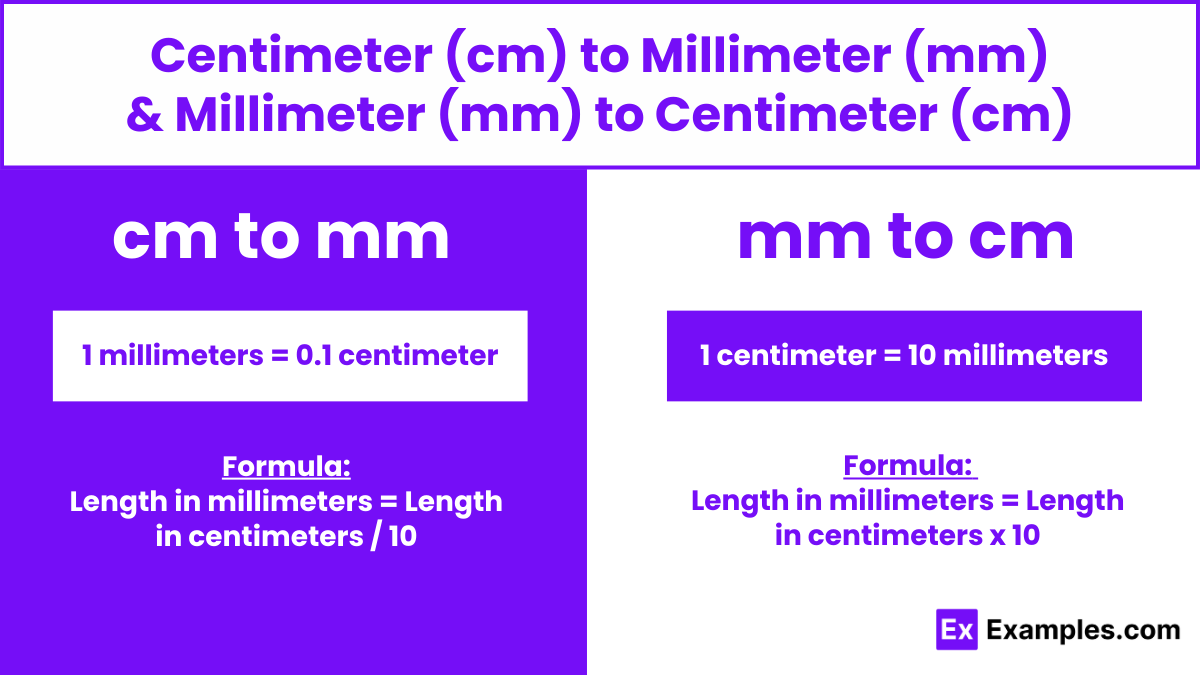

Let's break the chemistry of this conversion down without making it feel like a ninth-grade geometry nightmare. One inch is exactly 2.54 centimeters. This isn't an approximation; it’s an international standard agreed upon back in 1959. To find out what 3 3/8 inches looks like in the metric world, you first have to turn that fraction into a decimal.

📖 Related: Life for a Person in a Jail Cell: What You Don’t See on TV

Divide 3 by 8. You get 0.375. Add that to your 3 whole inches and you have 3.375 inches.

Now, grab a calculator—or just trust me here—and multiply 3.375 by 2.54. The result is exactly 8.5725 centimeters. In most real-world scenarios, like woodworking or sewing, you’re probably going to round that to 8.57 cm or even 8.6 cm if you’re just "eyeballing" it. But if you’re an engineer or a machinist? Those extra decimal places matter. A lot.

Why 8.5725 cm is the Magic Number for Designers

You might wonder why anyone cares about such a specific, awkward number. Why not just make things 8 cm or 9 cm?

It’s about legacy.

🔗 Read more: Why Are My Brakes Grinding: What’s Actually Happening to Your Car

Take the ISO/IEC 7810 ID-1 standard. This is the international benchmark for the size of a credit card. It’s technically defined as 85.60 mm by 53.98 mm. If you convert 3 3/8 inches (85.725 mm), you’ll notice it’s almost identical to the width of the card in your pocket. Wallet makers in the US often use 3 3/8 inches as their baseline because it gives that tiny bit of "wiggle room" needed for a card to slide in and out without a struggle.

Where You’ll Actually See 3 3/8 Inches in the Wild

It’s everywhere once you start looking.

If you're into home renovation, specifically lighting, you’ve probably run into the 3 3/8-inch hole saw. This is a common size for installing certain types of LED "wafer" lights or recessed cans. If you accidentally use an 8 cm drill bit because you're following a European manual, your light fixture simply won’t fit into the ceiling. You’ll be 0.57 centimeters short. That sounds like nothing, but in construction, it’s the difference between a clean install and a ruined piece of drywall.

- Machinery and Gauges: Many aftermarket automotive tachometers and speedometers are housed in 3 3/8-inch cups. If you're 3D printing a custom dashboard for a vintage car, you absolutely must use the 8.5725 cm conversion to ensure the gauge snaps into place.

- Photography: Large format lens boards and certain filter holders often hover around this dimension.

- Sports: Believe it or not, the diameter of a standard hockey puck is 3 inches, but once you get into specific specialized protective gear or case designs, that extra 3/8 of an inch shows up as a buffer zone.

The Problem with "Rounding Up"

Let’s be honest. Most people are lazy with measurements. We like round numbers. If someone tells you 3 3/8 inches is "basically 8 and a half centimeters," they are lying to you.

Being off by 0.725 millimeters might not matter if you’re cutting a piece of a 2x4 for a garden fence. Wood expands and contracts anyway. But if you're working with acrylic, metal, or glass, that error is massive. If you’re a hobbyist using a laser cutter or a CNC machine, entering 8.5 cm instead of 8.5725 cm will result in parts that don't join. You'll end up with a pile of expensive scrap material and a headache.

I’ve seen it happen in leatherworking too. Someone calculates their stitch line based on a rough 8.5 cm width for a card slot. They finish the piece, burnish the edges, and then realize the credit card won’t go in past the halfway mark. It’s heartbreaking.

👉 See also: Queen Mary I of England: What Most People Get Wrong About Bloody Mary

Converting Other Common Fractions

Sometimes it helps to see where 3 3/8 inches sits in the neighborhood of other common measurements.

- 3 1/4 inches: 8.255 cm

- 3 1/2 inches: 8.89 cm

- 3 5/16 inches: 8.41375 cm

You can see how 3 3/8 (8.5725 cm) sits right in that sweet spot. It’s a very "human" scale. It fits in the palm of a hand.

Tools for the Job

If you find yourself constantly jumping back and forth between these units, stop trying to do the math in your head. It’s 2026. Use a digital caliper. Most modern calipers have a button that toggles between inches (in decimals), inches (in fractions), and millimeters.

When you set a digital caliper to 3 3/8, it will usually display 3.375. Hit the button, and it jumps to 85.73 mm. This is the easiest way to visualize the physical space. If you’re a designer, set your software (like Figma or AutoCAD) to the unit of the manufacturer you’re working with. If the factory is in Shenzhen, work in cm/mm. If they’re in Ohio, stick to inches.

Actionable Steps for Perfect Precision

If you are currently working on a project that involves a 3 3/8 in cm conversion, follow these steps to avoid a "measure twice, cry once" situation:

- Identify the material: If you're working with metal or hard plastic, use the full decimal (8.5725 cm). If you're working with fabric, 8.6 cm is generally acceptable because the material has "give."

- Check your tools: Ensure your ruler or measuring tape is actually accurate. Believe it or not, cheap tape measures can be off by a millimeter or more across short distances.

- Account for the "Kerf": If you are cutting a 3 3/8 inch hole, remember that the blade itself has thickness. You need to center your cut so the final opening is 8.57 cm, not the path of the blade.

- Use the 2.54 rule: When in doubt, always multiply the decimal inch by 2.54. It is the only way to ensure you aren't carrying over rounding errors from a previous calculation.

Understanding that 3 3/8 inches translates to 8.5725 cm isn't just about math; it's about precision in craftsmanship. Whether you are building a custom car dash, sewing a wallet, or installing ceiling lights, that extra half-centimeter is the difference between professional work and a DIY disaster. Stick to the decimals and keep your tolerances tight.