If you’ve ever stood in the electrical aisle of a home improvement store staring at those heavy, plastic-wrapped coils, you know the sticker shock is real. Copper is expensive. And when you're looking at 6/3 wire with ground, you’re basically looking at the heavyweight champion of residential wiring. It's thick. It’s stiff. It’s incredibly heavy. But if you're trying to hook up a new electric range or a beefy EV charger, this is the stuff that keeps your house from burning down. Honestly, people mess this up all the time because they underestimate how much power modern appliances actually pull.

Wiring isn't just about getting the lights to turn on. It’s about heat management. When you run 50 amps through a wire, that copper gets warm. If the wire is too thin, it gets hot. Too hot, and you’ve got a structural fire on your hands. That’s why 6/3 wire with ground exists. It’s designed to handle that massive electrical "current" without breaking a sweat, provided you install it right.

What Does 6/3 Actually Mean?

Let's break the code because electrical naming conventions are kinda weird. The "6" refers to the gauge. In the American Wire Gauge (AWG) system, the smaller the number, the bigger the wire. So, 6-gauge is much thicker than the 12-gauge wire in your bedroom walls. The "/3" means there are three insulated conductors inside the jacket. Usually, these are black, red, and white. Then you have the bare copper ground wire.

Wait.

If there are three insulated wires and one bare wire, isn't that four wires total? Yep. In the world of Romex (NM-B), we don't count the ground in the primary number. So "6/3" is actually four physical strands of copper. You have two "hots" (black and red) to give you that 240-volt muscle, one neutral (white), and the ground for safety. If you only see two insulated wires, that’s 6/2, and it won't work for modern appliances that need a neutral for 120-volt clocks or displays.

Where You’ll Actually Use 6/3 Wire With Ground

Most DIYers encounter this wire when they realize their old oven won't plug into the new kitchen layout. Or, more commonly lately, when they buy a Tesla or a Rivian.

Portable EV chargers often pull 32 to 40 amps. To do that safely over long periods, you need a circuit that can handle a 50-amp load. That's the sweet spot for 6/3 wire with ground. According to the National Electrical Code (NEC), specifically Table 310.15(B)(16), 6 AWG copper wire with NM-B insulation is rated for 55 amps at 60°C. But since breakers usually come in 50-amp increments for residential use, that’s where it stays.

💡 You might also like: Why the Vitruvian Man Still Matters: More Than Just a Famous Drawing

Don't even think about using it for a welder if the manufacturer specifies 60 amps. You’d need to jump up to 4-gauge or use a different insulation type like THHN in conduit. It’s all about the temperature rating of the jacket. NM-B (the stuff you see in houses) has a lower heat tolerance than the wires pulled through metal pipes in a garage.

The Kitchen Powerhouse

Think about your range. Modern electric stoves have four or five burners plus a high-convection oven. If you have every burner going on Thanksgiving, you are pulling a massive amount of juice. Old 8-gauge wire might have cut it in the 70s, but today? Most pros won't pull anything less than 6/3 wire with ground for a new kitchen build. It provides that headroom so you aren't constantly tripping breakers or worrying about wire degradation over twenty years.

The Installation Nightmare Nobody Tells You About

Working with 6-gauge wire is like trying to bend a frozen garden hose. It’s stubborn. It doesn't want to go into the corner of the junction box. You’ll probably need "deep" boxes or even 4-inch square metal boxes with extension rings just to have enough "box fill" volume.

If you try to cram 6/3 wire with ground into a standard plastic single-gang box, you’re going to lose. You’ll either crack the box or the wires will push the outlet out so far the faceplate won't sit flush. It’s frustrating. Use a large 2-gang box or a specialized 50-amp power outlet box.

And then there's the stripping. You can't use your standard small wire strippers for this. You’ll need a utility knife or a dedicated large-gauge stripper. Be careful. If you nick the copper strands while removing the outer jacket, you’ve created a "hot spot" where the wire is now thinner and more prone to overheating. Take it slow.

Common Misconceptions and Safety Realities

One of the biggest mistakes people make is confusing NM-B with UF-B. If you are running 6/3 wire with ground out to a hot tub in the backyard, you cannot use standard indoor Romex. Even if it’s in a pipe. Why? Because moisture collects inside pipes underground. Indoor wire insulation will eventually rot, leading to a short. For anything outdoors or buried, you need 6/3 UF-B (Direct Burial) or individual THHN/THWN-2 wires inside a sealed PVC conduit.

Another thing: the "Ground" isn't optional.

📖 Related: Why Your Good Morning Good Morning Picture Habit Actually Changes Your Brain

Some old-school guys might tell you that you can skip the neutral or use the ground as a neutral. Don't listen to them. That’s how people get shocked by their appliance frames. The neutral is a current-carrying conductor; the ground is a safety path. They serve two totally different masters.

Copper vs. Aluminum

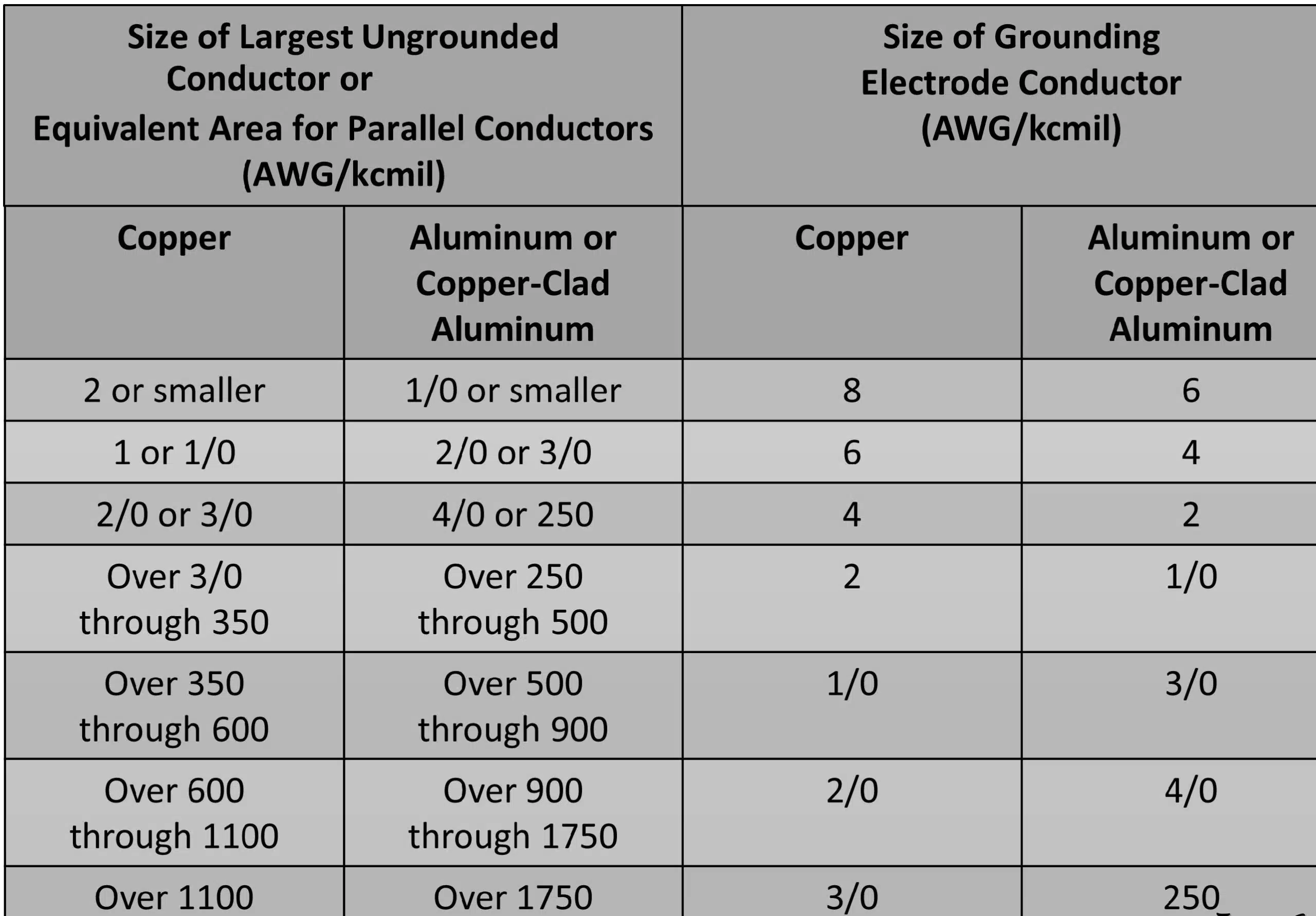

You might see 6/3 aluminum wire for a much lower price. Resist the urge. Aluminum doesn't carry current as efficiently as copper. To get the same 50-amp capacity as 6/3 wire with ground in copper, you’d have to jump up to 4-gauge or even 2-gauge in aluminum. Plus, aluminum requires special antioxidant paste at the connections to prevent corrosion. For a single run to an appliance, copper is almost always worth the extra money for the peace of mind.

Calculating the Cost and Value

Right now, a 50-foot roll of 6/3 NM-B might set you back $150 to $200 depending on the market. It fluctuates with the global price of copper. Is it worth it?

If you're installing a 14-50R outlet for an EV, the wire is the most expensive part of the job besides the labor. But think of it as an investment in your home's infrastructure. Using 6/3 wire with ground ensures that even if you upgrade to a faster charger or a more powerful appliance later, the "pipes" in your walls are already big enough to handle it. You won't have to rip the drywall open again in five years.

Practical Steps for Success

Before you go out and buy a 100-foot spool, do a few things first.

Measure your run. Then add 10 feet. You do not want to be six inches short when you're trying to reach the bus bar in your electrical panel. Splicing 6-gauge wire is expensive and requires massive junction boxes, so it's better to have a few feet of "scrap" than a wire that doesn't reach.

- Check your local building codes. Some cities require all 6-gauge wire to be in conduit, even inside walls.

- Buy the right breaker. A 50-amp double-pole breaker is the standard companion for 6/3 wire with ground.

- Get a torque screwdriver. Most 50-amp outlets and breakers specify a "torque setting" (usually in inch-pounds). If it’s too loose, it arcs. If it’s too tight, you crush the wire. Professionals actually use torque tools to meet modern NEC requirements.

- Plan your route. Avoid drilling through floor joists if you can help it; 6/3 is thick enough that it requires a 1-inch hole, which can weaken structural members if not centered perfectly.

If you’re feeling overwhelmed, that’s normal. Electricity is dangerous. If you aren't comfortable opening your main service panel—the place where "the spicy air" lives—call an electrician. Have them pull the 6/3 wire with ground for you. You can do the grunt work of stapling it to the studs, but let a pro handle the final connections to the 240V bus. It’s cheaper than a fire insurance claim.

Make sure you use large-diameter cable staples specifically rated for 6/3. Standard staples for 12/2 will pinch the jacket and cause a failure point. Look for the wide plastic insulated staples. Space them every 4 feet and within 12 inches of every box. This keeps the weight of that heavy copper from pulling on the terminals over time. Once it’s in, you’re set for decades.