The aerospace supply chain is a mess. Honestly, that’s the only way to put it if you’re looking at the raw data coming out of the first few weeks of 2026. While the headlines usually focus on flashy new plane orders at the Paris or Farnborough airshows, the real story is happening in the grit of Tier 3 machine shops and engine casting plants.

You’ve probably heard that things are "recovering," but that’s a half-truth at best. Aerospace supply chain news today is dominated by a weird paradox: demand for new aircraft is higher than it’s ever been, yet the physical ability to build them is stuck in a bottleneck that feels like a permanent traffic jam.

Why the "Glider" Problem is Back

Remember when Airbus had to build "gliders"—essentially finished airplanes sitting on the tarmac without engines? Well, it’s happening again. Christian Scherer, the outgoing CEO for Airbus commercial aircraft, recently pointed out that engine deliveries for the bestselling A320neo are still a massive headache.

It’s not just one thing. It’s a pile-on.

First, you have the durability issues with the LEAP engines. GE Aerospace and RTX (Raytheon) are scrambling to fix these while also trying to ramp up production. Then you have the fuselage panel situation. Just last month, Airbus had to lower its delivery targets because of faulty panels. It’s like a game of Whac-A-Mole; you fix the engine shortage, and suddenly the seats aren't arriving. You fix the seats, and the titanium for the landing gear is stuck in a trade dispute.

The numbers are pretty staggering. IATA just dropped a report suggesting that these bottlenecks could cost the airline industry over $11 billion this year. Why? Because airlines are forced to keep old, fuel-guzzling planes in the air way longer than they planned. They’re leasing engines at a 20-30% premium just to stay operational.

The Rise of the "Micro-Factory" and 3D Printing

Because the traditional supply chain is so brittle, companies are starting to get weirdly creative. We are seeing a massive shift toward additive manufacturing (3D printing). This isn't just for plastic prototypes anymore.

China just tested a 3D-printed turbojet engine in flight late last year. That’s a huge deal. Closer to home, Park Aerospace is dropping $50 million on a new plant in the Midwest just to keep up with the demand for composite materials. They grew 20% last year but still missed nearly a million dollars in shipments because of—you guessed it—supply chain hiccups.

✨ Don't miss: Why the Currency Converter Jordanian Dinar to US Dollar Always Seems to Stay the Same

The "just-in-time" model is basically dead.

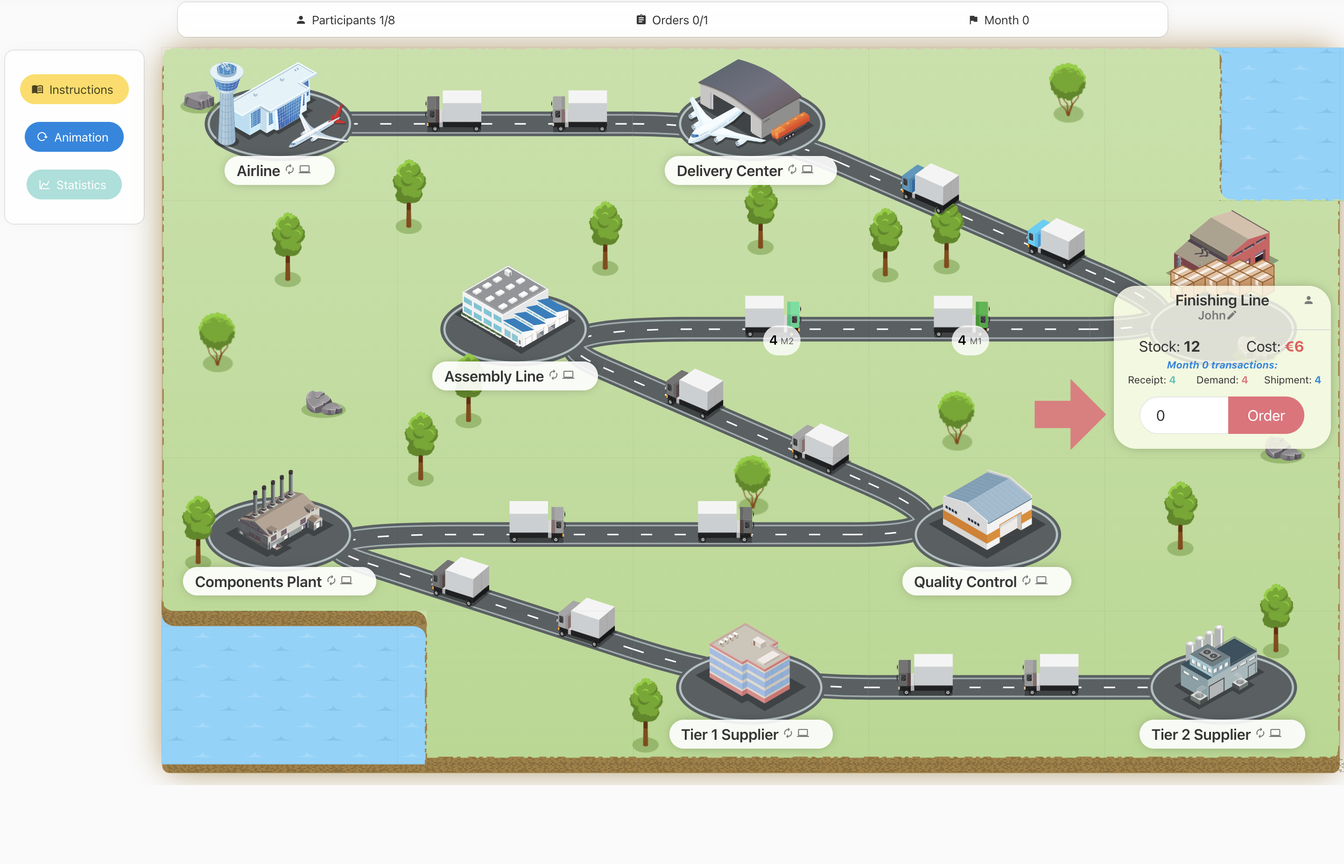

Everyone is moving toward "just-in-case" inventory. Companies like Boeing are looking at modular actuators—basically "plug and play" parts that can be certified faster and swapped out easier. They’re working with startups like Salient Motion to make this happen. It’s a total shift in how we think about aircraft assembly.

The Labor Gap Nobody Wants to Talk About

You can buy all the 3D printers and titanium you want, but you still need people who know how to use them. The UK industry group ADS is screaming from the rooftops that the biggest hurdle in aerospace supply chain news today is a lack of skilled workers and capital.

It’s a global problem.

- France seems to have figured out some of its hiring issues, but now they're obsessed with "sovereignty"—basically trying to make sure they aren't reliant on US or Chinese parts.

- The US is dealing with a new political landscape where executive pay and shareholder awards are under fire. This makes long-term investment in factory floor upgrades a hard sell for some boards.

- MRO (Maintenance, Repair, and Overhaul) shops are seeing a 600% increase in cyberattacks. When the systems that track part safety get hacked, the whole supply chain grinds to a halt.

Real Talk: The 2026 Forecast

If you’re waiting for things to go back to "normal," you’re going to be waiting until at least 2031. IATA estimates a delivery shortfall of at least 5,300 aircraft. The backlog is now over 17,000 planes. That is nearly 12 years of work if we stopped taking orders today.

The reality is that the aerospace supply chain is being rebuilt in real-time. It’s becoming more digital, more localized, and significantly more expensive.

Actionable Insights for Industry Players:

- Ditch the Single Source: If you only have one supplier for a critical component, you are one strike away from a shutdown. Multi-sourcing is no longer an option; it's a survival requirement.

- Invest in "Digital Twins": Companies like PepsiCo are showing the way here, but aerospace is catching up. Using AI to simulate your supply chain before a crisis hits can catch 90% of issues before they happen.

- Focus on Aftermarket: With new plane deliveries delayed, the real money is in keeping the old fleet flying. Spare parts and MRO services are the only things keeping the lights on for many Tier 2 suppliers.

- Audit Your Cybersecurity: Ransomware isn't just for banks anymore. Your production data is your most valuable asset. If you can't prove the provenance of a part because your database is locked, that part is scrap metal.

The aerospace industry is in a "healing" phase, but it's a slow, painful one. The winners in 2026 won't be the ones with the biggest order books, but the ones who actually have the parts to finish the planes.