Walk through any suburban neighborhood built in the last thirty years and you’ll see it. That smooth, clean, Mediterranean look. It looks like masonry, but if you tap on it, it sounds hollow. That’s an Exterior Insulation Finishing System, or EIFS. People often just call it "synthetic stucco." Honestly, it’s one of the most brilliant pieces of building science ever invented—and also one of the most hated.

It’s a literal blanket for your house.

Think about how we usually insulate homes. We stuff pink fiberglass between wooden studs. The problem? Those studs act like thermal bridges, letting heat leak out like a sieve. EIFS changes the game by wrapping the outside of the structure in continuous rigid insulation. It’s incredibly efficient. But back in the late 90s, the industry hit a massive wall—literally. Thousands of homes in places like North Carolina and Vancouver started rotting because water got trapped behind the foam. It became a legal nightmare. If you’re looking at a house with EIFS today, or thinking about installing it, you have to understand the difference between the "barrier" systems of the past and the "drainage" systems required by modern building codes.

How EIFS Actually Works (When It’s Done Right)

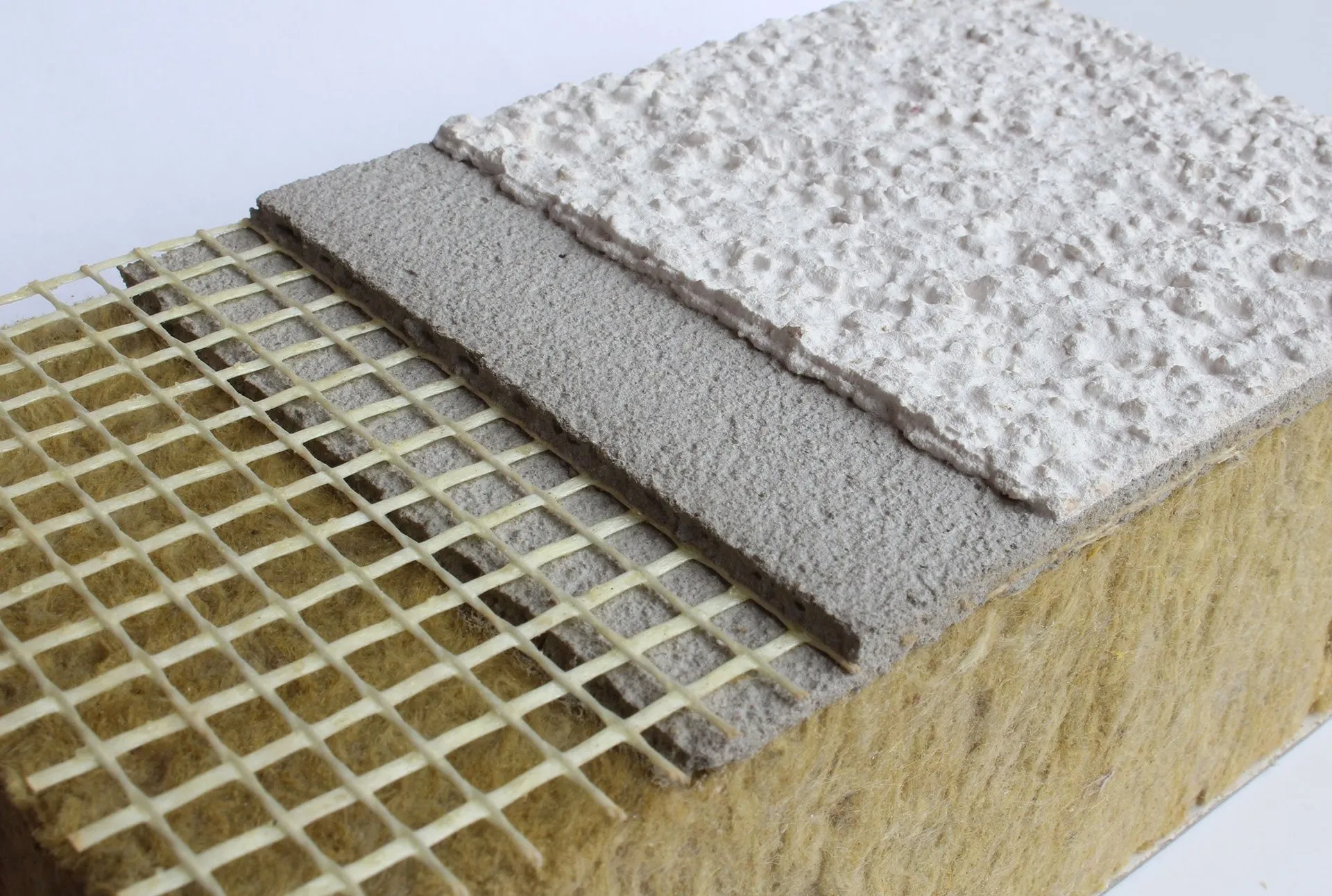

Most people assume it’s just thick paint over foam. It’s way more complex. A modern EIFS assembly is a multi-layered sandwich. First, there’s a water-resistive barrier (WRB) applied directly to the sheathing. Then comes the drainage plane—basically a way for moisture to escape if it ever sneaks in.

After that, you’ve got the Expanded Polystyrene (EPS) insulation boards. These are glued on with a specialized adhesive. Then comes the "base coat," which is a reinforced layer of fiberglass mesh embedded in a polymer-modified cement. Finally, the finish coat gives it that color and texture. Because the finish is acrylic-based, it’s flexible. It doesn’t crack as easily as traditional hard-coat stucco, which is basically just a thin layer of concrete.

The thermal performance is wild. According to the Oak Ridge National Laboratory, EIFS is significantly more energy-efficient than brick, vinyl, or conventional stucco. It reduces air infiltration by as much as 8% compared to standard cladding. You’re basically living in a Yeti cooler.

The Moisture Trap: Why People Are Still Scared

The "Great Stucco Crisis" of the late 20th century wasn't actually a failure of the EIFS material itself. It was a failure of the system's philosophy. Back then, it was designed as a "face-sealed" or "barrier" system. The idea was that the outer skin would be 100% waterproof.

But houses move.

Windows leak. Caulking dries out. When water inevitably got behind the foam in those early systems, it had nowhere to go. It sat against the plywood sheathing and turned it into mush. I’ve seen houses where the OSB sheathing looked like wet oatmeal because of a poorly flashed window.

Today, the EIFS Industry Members Association (EIMA) mandates a "drainage" requirement. If water gets in, there are tiny gaps or grooved foam boards that allow gravity to pull the water down and out through "weep holes" at the bottom of the wall. If your contractor isn't talking about drainage mats or liquid-applied barriers, run away. Quickly.

Critical Components You Can't Skip

- Back-wrapping: This is where the fiberglass mesh is wrapped around the edges of the foam boards at terminations. If you see raw foam at the bottom of a wall, the installer cut corners.

- Expansion Joints: Large walls need room to breathe. Without joints, the system will buckle.

- Proper Flashing: This is the #1 failure point. Kick-out flashing at roof-to-wall intersections is non-negotiable.

Real-World Costs vs. Long-Term Value

EIFS is not cheap.

Usually, you’re looking at anywhere from $10 to $18 per square foot installed. That’s a lot more than vinyl siding, which might run you $5 to $8. But you’re getting two products in one: your exterior finish and your continuous insulation.

You also have to factor in the "curb appeal" tax. High-end EIFS jobs can mimic limestone, granite, or even wood planks. If you're building a custom home, the architectural flexibility is insane. You can create cornices, arches, and deep window sills easily because the "stone" is actually just sculpted foam.

Maintenance: It’s Not "Set It and Forget It"

One big misconception is that synthetic stucco is maintenance-free. It isn't. Because the finish is somewhat soft, it can be punctured. A stray rock from a lawnmower or a rogue hailstone can create a hole. If you don't patch that hole, you're inviting moisture into the core.

Cleaning is another issue. The texture of EIFS tends to trap dust and can grow algae in damp, shaded areas. You can’t just blast it with a 4000 PSI pressure washer. You’ll destroy the finish and potentially force water into the system. You use a low-pressure wash with specialized detergents.

Does it affect your insurance?

Sometimes, yeah. In certain regions, insurance companies are still wary of EIFS because of those 90s lawsuits. You might pay a higher premium, or some carriers might refuse to cover "barrier" EIFS altogether. Always check your policy before buying a home with this cladding. If the house was built after 2000, you're usually in much better shape because it likely has a drainage system.

The "Hard Coat" vs. "Synthetic" Debate

It's common to hear contractors argue about which is better. Traditional "hard coat" stucco is a three-layer system of Portland cement, lime, and sand over a metal lath. It’s tough as nails. You can hit it with a hammer and it won't dent.

💡 You might also like: Why Love of the Past NYT Is Trending and What It Says About Us

But it’s heavy. It’s prone to "spiderweb" cracking as the house settles.

EIFS is "soft," but it handles building movement much better. It also offers a higher R-value (insulation power). A 1-inch thick piece of EPS foam provides an R-value of about 3.8 to 4.0. In many modern climate zones, building codes now require this kind of continuous insulation to meet energy targets. So, in many ways, the industry is moving toward EIFS-style logic regardless of the final aesthetic.

How to Tell if an EIFS Wall is Failing

If you’re a homeowner, you need to be a detective. Look for these red flags:

- Heavy staining at the corners of windows. This often means water is running behind the finish rather than over the top of it.

- Bulging or "pillowing." This happens when the adhesive fails, usually due to moisture.

- Cracks larger than a credit card's thickness. Tiny hairline cracks are common, but anything bigger is an entry point for rain.

- Soft spots. Press on the wall near the ground or around windows. If it feels spongy, the wood underneath is likely compromised.

Impact on Resale Value

Honestly, it’s a mixed bag. In some markets, like Florida or Arizona, EIFS and stucco are the gold standard. In the Pacific Northwest or the East Coast, some buyers are still terrified of "the stucco problem."

If you're selling an EIFS home, it is incredibly smart to get a professional moisture probe test done before you list it. A certified inspector will literally poke tiny holes (which they seal afterward) into the system to check the moisture content of the wood sheathing. Having a "dry" report is the only way to satisfy a skeptical buyer.

Actionable Steps for Homeowners and Builders

- Verify the System: If you are installing new EIFS, ensure it is a "Class PB" (Polymer-Based) system with a liquid-applied air and water barrier. Brand names like Dryvit, Sto, and Master Wall are industry leaders with robust warranties.

- Annual Inspection: Every spring, walk the perimeter of your house. Check the caulking around every window, door, and light fixture. If the sealant is peeling or gapping, replace it with a high-quality silicone or polyurethane sealant immediately.

- Keep Soil Away: Ensure there is at least a 6-inch gap between the bottom of the EIFS and the soil or mulch. Pests like termites love the space between the foam and the house, and soil wicks moisture into the system.

- Hire Certified Pros Only: Don't let a general "siding guy" do EIFS. Ensure your contractor is specifically trained by the manufacturer and has a certificate from the EIFS Industry Members Association.

- Check the Weep Holes: Ensure that any drainage tracks at the bottom of the wall aren't clogged with dirt or painted shut. These are the lungs of your house; if they can't breathe, the system fails.