Fresh cane juice is incredible. If you've ever stood on a humid street corner in Mumbai or Cairo and watched a vendor shove stalks into a heavy-duty sugar cane press machine, you know that cloudy, lime-tinted liquid is basically liquid gold. It's sweet, but it’s earthy. It's refreshing in a way a soda could never be. But here’s the thing—most people looking to get into the juice business or even just upgrade their farm setup end up buying equipment that breaks within six months because they don't understand the physics of torque.

Cane is tough. It’s a grass, sure, but it’s essentially a woody stick filled with silica.

To get the juice out, you aren’t just "squeezing" it. You are literally crushing the cellular structure of a fibrous plant. This requires massive pressure. If your machine isn't built with the right grade of stainless steel or the gear ratio is off, you’re basically just making a very expensive paperweight. Honestly, it’s frustrating to see how many "lightweight" models are marketed to small businesses when they simply can't handle the load of a 20-pound bundle of stalks.

The Brutal Physics of the Sugar Cane Press Machine

Most folks think any motor will do. They’re wrong.

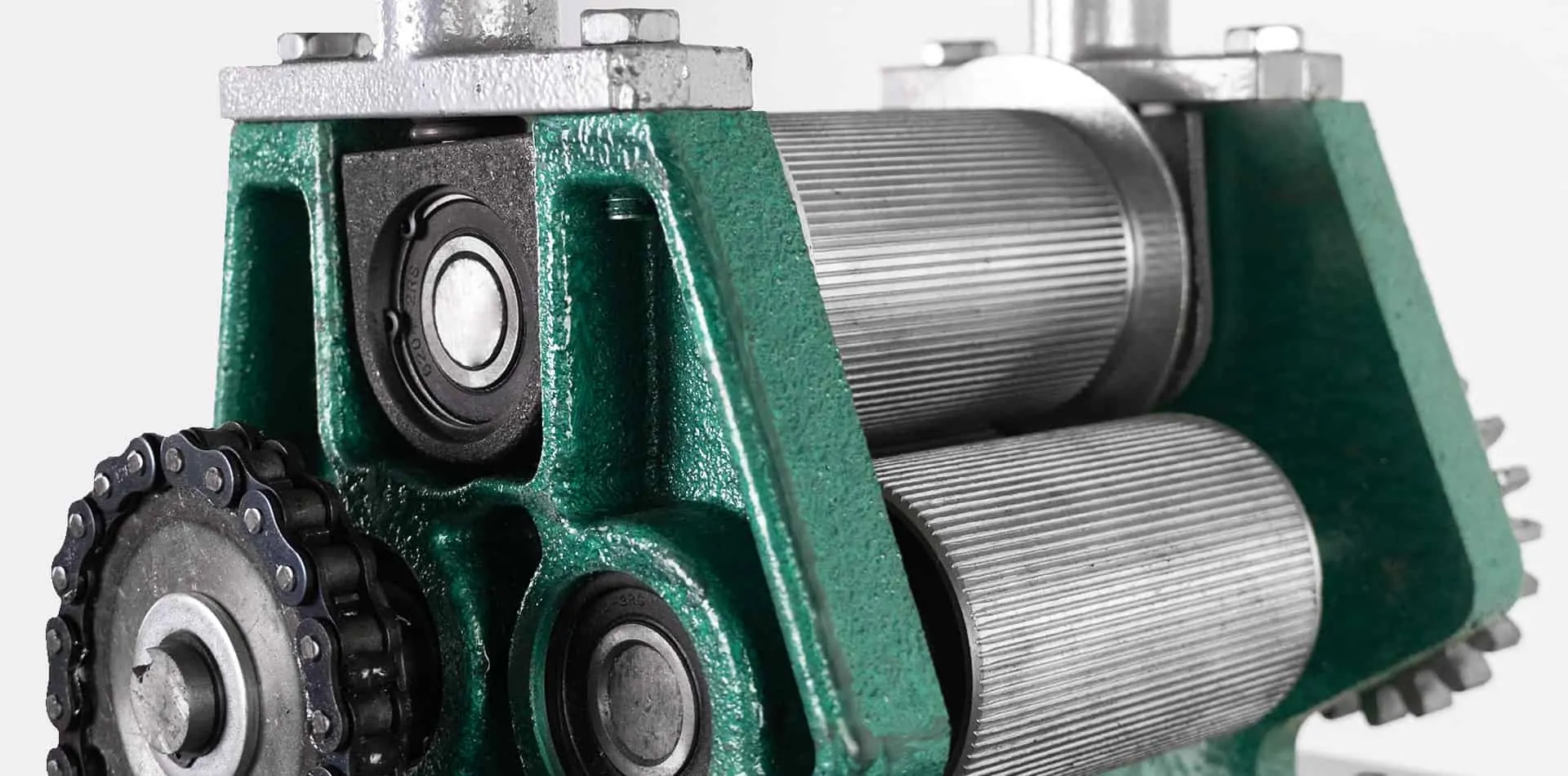

A standard sugar cane press machine relies on three rollers. These rollers are usually knurled—meaning they have a textured pattern—to grip the slippery outer skin of the cane. As the stalk passes through the first gap, it’s cracked. The second gap is where the real magic (and the most stress) happens. This is where the juice is literally rung out of the fibers.

👉 See also: NextEra Energy Stock Price: What Most People Get Wrong

If you look at high-end industrial models, like those from manufacturers such as Amisy or ProduceMate, they use cold-pressed technology. Why? Because heat is the enemy of flavor. When a low-quality motor works too hard, it generates heat. That heat transfers to the rollers, which then "cooks" the juice slightly. It changes the enzyme profile. It makes it taste... off. Metallic, almost.

You want high extraction rates. A good machine should hit about 80% extraction in a single pass. If you have to run the bagasse—that’s the leftover dry fiber—through the machine three or four times, you’re wasting time. And time is money.

Manual vs. Electric: Choosing Your Weapon

Manual presses are great for nostalgia. They look cool. You see them at historical reenactments or tiny boutique stalls. But let’s be real: cranking a wheel by hand for eight hours is a nightmare. It’s a workout you didn’t ask for.

Electric machines are where the industry lives now. But even here, there’s a massive divide.

- Battery-Operated Portable Units: These are trendy for food trucks. They’re quiet. You can run them off a deep-cycle battery. But they often struggle with thicker stalks of Saccharum officinarum (the most common sugar cane species). If the cane is too thick, the motor stalls.

- Heavy-Duty Plug-in Models: These use 400W to 755W motors. They are beasts. They can chew through anything.

- The "Silent" Models: Some newer tech uses gear-reduction systems to keep the noise down. This is huge if you’re operating in a quiet cafe or a high-end mall.

What Most People Ignore: The Cleaning Nightmare

Here is the secret nobody tells you until you’re elbow-deep in sticky residue at 11 PM. Sugar cane juice is roughly 15% to 20% total soluble solids. It’s a literal glue. If you don’t clean your sugar cane press machine properly, the juice ferments inside the rollers.

✨ Don't miss: Is Polymarket Legal in Texas? What Most People Get Wrong

It gets gross fast.

You need a machine with a "one-piece" juice tray or rollers that are easily accessible. Some of the cheaper models from overseas have nooks and crannies that are impossible to reach without a full teardown. Avoid those. Look for 304-grade stainless steel. It’s non-reactive. It won’t rust when it hits the acidic lime juice people often add to the mix.

The Business Case for Cold-Pressed Cane Juice

Is it actually profitable?

In 2024 and 2025, we saw a massive surge in "functional beverages." People are moving away from processed sugars and toward raw, unrefined sources. Sugar cane juice is loaded with potassium, magnesium, and iron. It’s got a lower glycemic index than refined sugar.

If you’re running a juice bar, the margins are insane. A single stalk of cane costs pennies. A 12-ounce cup of fresh juice can sell for $5 to $8 in urban markets like Los Angeles or New York. Even after factoring in the cost of the sugar cane press machine, most businesses see a return on investment within the first three to four months of operation.

But you have to sell the experience. The "theatrics" of the machine matter. People want to see the cane go in and the juice come out. It’s transparent. It feels honest.

Maintenance and Longevity

Don't ignore the bearings.

The bearings in a press take a pounding. Every time a stalk goes through, there’s a radial load trying to push those rollers apart. Professional-grade machines use oversized, sealed bearings. If you hear a high-pitched squealing? That’s your machine dying. Stop it immediately. Grease it.

Also, check the "teeth" on your rollers. Over time, the silica in the cane acts like sandpaper. It will smooth out the knurling. When that happens, the machine starts slipping. You’ll find yourself pushing the cane in with a pusher tool, which is dangerous and slow. Some high-end brands offer replaceable roller sleeves. That’s a feature worth paying for.

💡 You might also like: Gold Rate Chart in Indian Rupees: What Most People Get Wrong

Making the Final Decision

Buying a press isn't just about the price tag. It’s about the "throughput."

How many gallons do you need per hour? If you’re a small farm stand, a tabletop 3-roller model is plenty. If you’re supplying a bottling plant, you need a continuous-feed system with a built-in filtration screen.

Make sure the machine has an emergency stop button. It sounds obvious, but you’d be surprised how many "budget" models skip this. Cane juice is sticky, your hands get wet, and things can happen. Safety isn't optional.

Actionable Next Steps

- Measure Your Stalks: Before buying, measure the average diameter of the cane you’ll be sourcing. If your cane is consistently over 2 inches thick, you need a wide-mouth industrial press, not a consumer model.

- Verify the Steel Grade: Demand 304 or 316 stainless steel certification from the seller. If they can't provide it, the rollers might be plated, which will flake off into your juice over time.

- Test the Extraction: Ask for a video of the specific unit running a single pass. The bagasse should come out dry enough to start a fire with. If it's still dripping, the machine is inefficient.

- Check Local Health Codes: Many jurisdictions require "NSF" certification for commercial juice equipment. Check this before you drop three grand on a machine you can't legally use in a restaurant.

- Plan for Waste: You’re going to have a lot of fiber left over. Some businesses compost it; others dry it and use it as eco-friendly packaging filler or fuel. Have a plan for the "waste" before it piles up behind your shop.