You’re driving down a flat stretch of highway, hands resting lightly on the wheel, and suddenly you realize you're drifting toward the shoulder. You nudge it back. It drifts again. It’s annoying, sure, but it’s also a sign that your suspension is basically fighting itself. Most people think "alignment" means something is wrong with the rubber tires themselves. It isn't. Not really. When you ask how is a tire alignment done, you’re actually asking how a technician uses high-tech lasers to square up your car's steering and suspension joints so they point in the exact direction the manufacturer intended.

It’s precise work. We’re talking about measurements so small they’re calculated in fractions of a degree. If your alignment is off by even a tiny bit, it's like walking with one shoe pointed slightly inward. You'll get where you're going, but your knees—or in this case, your tires—are going to pay the price.

The prep work nobody sees

Before the car ever touches the alignment rack, a good mechanic does a "shake down." This is vital. Honestly, there is no point in aligning a car if the ball joints are shot or the tie rods have more play than a playground swing. They’ll pull the car into the bay, lift it slightly, and literally grab the tires to see if they wiggle. If something is loose, that part gets replaced first.

Once the suspension is cleared, the car rolls onto the alignment rack. This is a massive, drive-on lift that has built-in "slip plates." These plates allow the wheels to move freely without the friction of the floor, which is the only way to get an honest reading of where the wheels want to sit.

Then come the targets. You've probably seen them—those weird, checkerboard-patterned panels that look like something out of a sci-fi movie. The tech clamps these onto each wheel. High-resolution cameras mounted on a tower in front of the car "see" these targets. By tracking the position of the patterns as the car rolls forward and backward a few inches, the computer calculates the exact orientation of every wheel in 3D space. It's incredibly accurate.

The three big adjustments

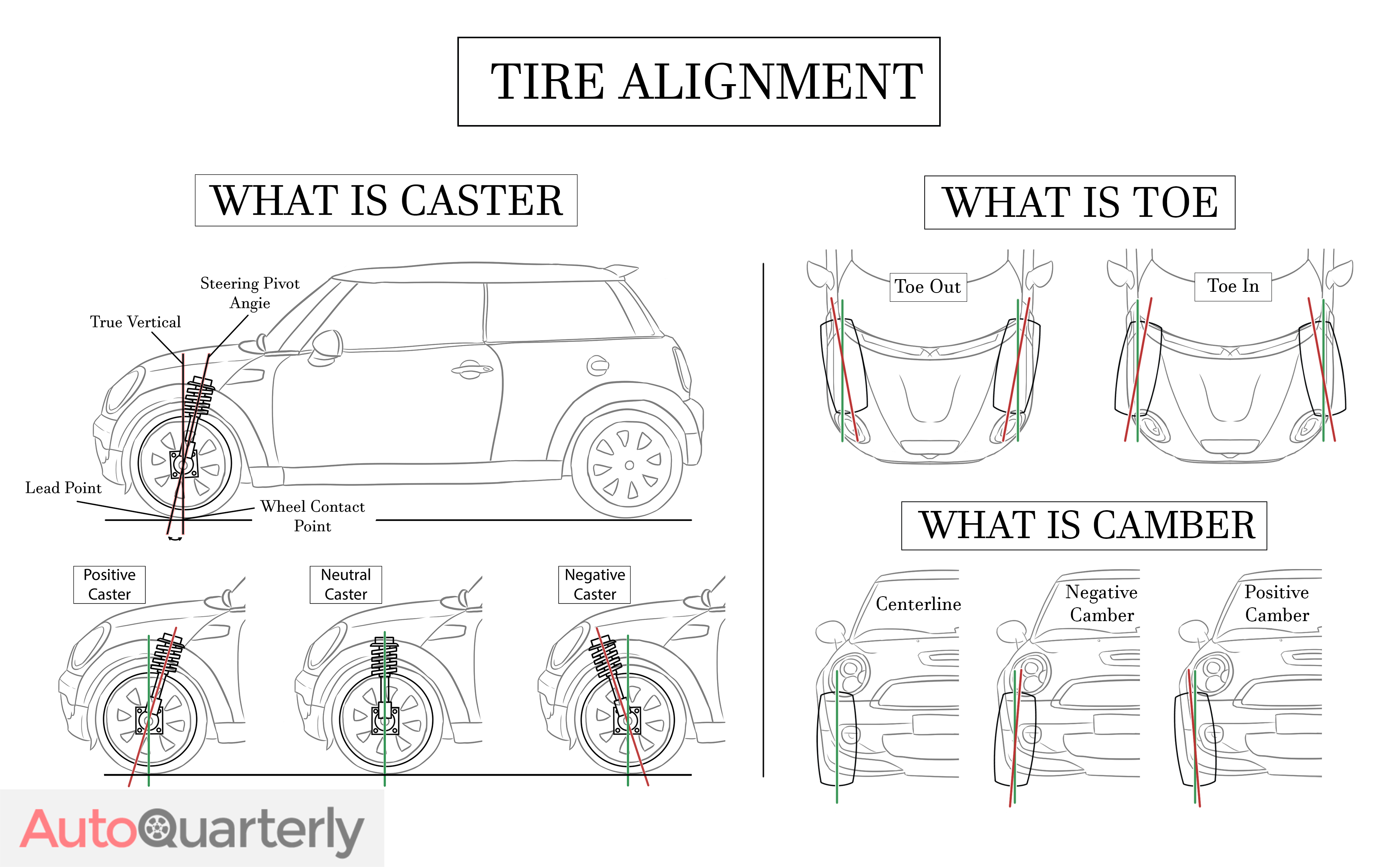

Now we get to the heart of how is a tire alignment done. There are three primary angles the tech is looking at: Toe, Camber, and Caster.

Toe: The biggest tire killer

Imagine looking down at your own feet. If you point your toes toward each other, that’s "toe-in." If you point them out like a duck, that’s "toe-out." Cars are the same. Most passenger cars are set with a tiny bit of toe-in to help with stability at high speeds. If this is off, your tires "scrub" against the road. Instead of rolling cleanly, they’re being dragged sideways. This creates "feathering," where the edges of the tread blocks feel sharp in one direction and smooth in the other. To fix this, the mechanic adjusts the tie rods, lengthening or shortening them until the wheels are parallel.

Camber: The tilt factor

Camber is the inward or outward tilt of the tire when viewed from the front. If the top of the tire leans toward the engine, that’s negative camber. A little bit of negative camber is actually great for cornering—think of a race car leaning into a turn. But too much? You’ll bald the inside edge of your tire in a few thousand miles. On many modern cars, especially those with strut-based suspensions, camber isn't always adjustable without aftermarket kits, but on trucks and performance cars, it's a major part of the process.

Caster: The steering "feel"

Caster is the hardest one to visualize. Think of a bicycle fork. The fork pivots at an angle so the wheel sits out in front of the steering axis. This is what makes the steering wheel "return to center" after you make a turn. If your caster is uneven, the car will pull toward the side with less caster. It doesn’t usually cause tire wear, but it makes the car feel nervous and twitchy on the road.

✨ Don't miss: I Never Received a Package From Amazon: What to Actually Do When Your Stuff Vanishes

Precision under pressure

The mechanic is under the car with a wrench in one hand and their eyes on a computer monitor. As they turn an adjustment bolt, they see the "red" bars on the screen slowly move into the "green" zone. It's a game of millimeters.

Sometimes, bolts are rusted solid. In the Rust Belt, a "simple" alignment can involve a blowtorch and a lot of swearing. The tech has to heat up the adjustment sleeves just to get them to budge. Once everything is centered, they lock the steering wheel in a straight-ahead position using a specialized tool. There is nothing worse than a car that drives straight but has a crooked steering wheel.

Modern cars have an extra layer of complexity: the Steering Angle Sensor (SAS). Because of Electronic Stability Control and Lane Keep Assist, the car's computer needs to know exactly where "center" is. After the mechanical bits are bolted down, the tech often has to plug a scan tool into the OBD-II port to calibrate the sensor. If they skip this, your car might think you're in a permanent skid and start braking individual wheels randomly. Not fun.

Why you can't just "eyeball" it

You’ll hear old-timers talk about doing alignments with a piece of string and a tape measure. While that can get you "close enough" to get to the shop after a repair, it’s nowhere near the precision required for modern radial tires.

A heavy pothole hit can bend a strut or knock an eccentric bolt out of place. Even just the natural settling of rubber bushings over 50,000 miles can change the geometry. This is why most shops recommend a check every year or whenever you buy new tires. If you’re spending $800 on a set of Michelins, spending $100 to make sure they aren’t destroyed in six months is basically an insurance policy.

Real-world signs you're out of whack

It isn't always a pull to one side. Sometimes it's a vibration that feels like a tire balance issue but is actually the wheels fighting each other. Other times, it's just a "heavy" feeling in the steering.

Look at your tires. Right now. If the inside edge is significantly more worn than the outside, you have a camber issue. If the tread feels like a saw blade when you run your hand over it, your toe is out. If you have to hold the steering wheel at the 11 o'clock position just to go straight, your thrust angle is off—meaning your rear wheels aren't following your front wheels properly.

Actionable steps for your next visit

Knowing how is a tire alignment done helps you talk to your mechanic without getting fleeced. When you go in, don't just ask for an alignment. Ask for the "Before and After" printout.

Every modern alignment machine prints a report. It shows the factory specifications next to your car’s actual measurements. If a shop won't give you that paper, they probably didn't do the job right. Look for the "Total Toe" and make sure the "Steer Ahead" is at zero.

If they tell you they can't align it because a part is worn out, believe them. Trying to align a car with bad ball joints is like trying to build a house on a foundation of Jell-O. Fix the parts first, then get the alignment. Your steering—and your wallet—will thank you in the long run.

✨ Don't miss: Nail Art Blue Flowers: Why This Specific Look Is Taking Over Salons Right Now

Final check: drive the car on a flat road immediately after the service. Let go of the wheel for one second. It should track straight. If it doesn't, turn around and go back to the shop. Occasionally, tires "set" into a wear pattern and will pull even if the alignment is perfect; a good tech will know how to rotate the tires to see if the pull follows the tire or stays with the car.

Next Steps for You:

- Check your tire pressure: Incorrect PSI can mimic alignment pull. Ensure all tires are at the door-sticker recommendation before assuming the alignment is bad.

- The "Hand Test": Run your palm across the tread of your front tires. If it feels rough or "scaly" in one direction, book an alignment check this week.

- Inspect your wheels: Look for any flat spots or bends on the inside and outside of the rims, as a bent wheel cannot be "aligned" out of a vibration.