You’re standing over a pile of sawdust with a loose, dull loop of metal in one hand and a heavy power tool in the other. It’s frustrating. Honestly, figuring out how to install chainsaw chain for the first time feels a bit like solving a Rubik’s cube that can actually cut your fingers off if you get it wrong. Most people just wing it. They slap the chain on, crank the tensioner until it's tight as a piano wire, and wonder why the bar starts smoking five minutes later.

Getting this right isn't just about making the tool work. It's about not ruining a $500 Husqvarna or Stihl because you didn't seat the drive links. It's about safety. A chain that flies off at 13,000 RPM is basically a whip made of razor blades.

🔗 Read more: Converting 1400 ml to l: Why Most People Mess Up the Math

The Directional Mistake Everyone Makes

If you look at a chainsaw chain, it looks symmetrical at a glance. It isn't. The most common mistake beginners make—and even pros when they’re tired—is putting the chain on backward. I’ve seen guys spend twenty minutes trying to buck a log, wondering why the saw is just polishing the wood instead of cutting it.

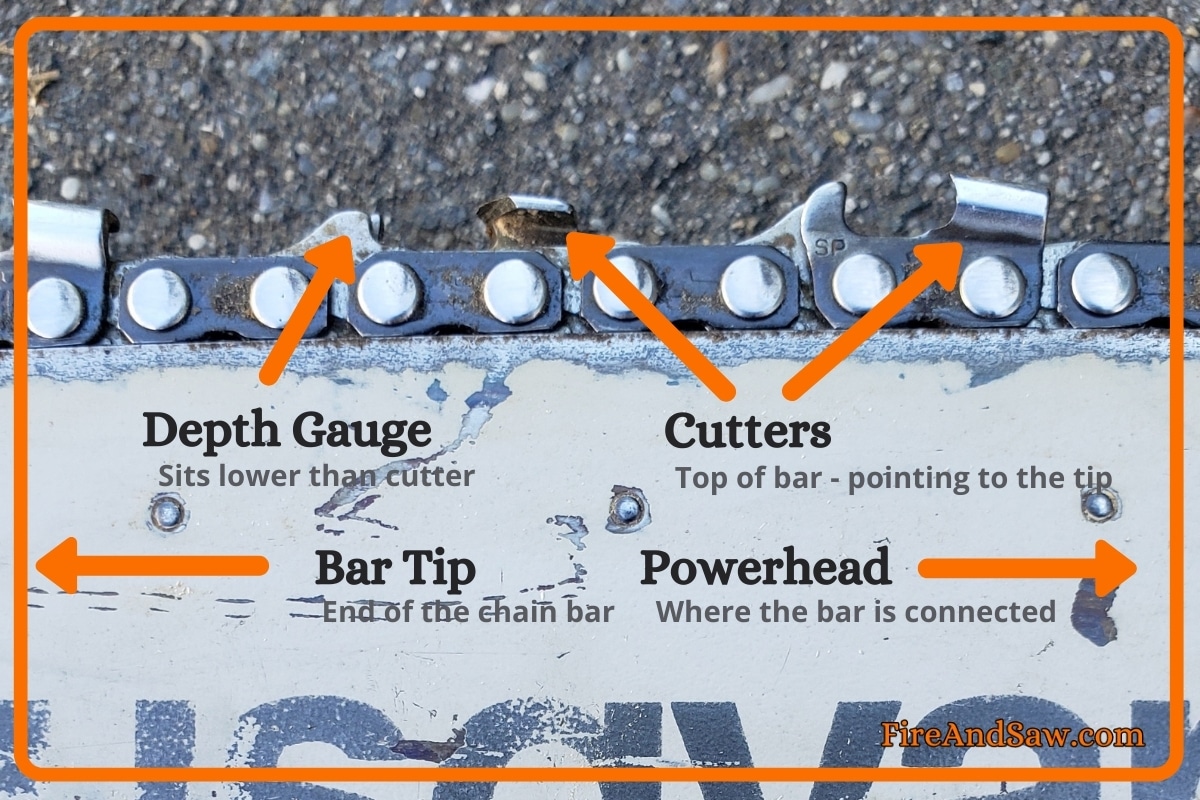

Look at the top of the bar. The sharp "hood" of the cutter must face away from the power head. The cutting edge should be pointing toward the tip of the bar. Most modern chains from brands like Oregon or Stihl actually have a little arrow stamped into the metal of the drive link. Follow that arrow. If you install it backward, the "rakers" (those little bumps in front of the cutters) will hit the wood first, and the teeth won't bite at all.

Prepping the Saw for the New Loop

Don't just yank the old chain off. First, make sure the engine is off. Obviously. If you're working on a battery-powered saw like a Milwaukee M18 or a DeWalt, pull the battery out. It’s way too easy to bump a trigger while you’re manhandling the bar.

Loosen the bar nuts. You’ll need a "scrench"—that half-screwdriver, half-wrench tool that came with the saw. You don't need to take the nuts all the way off yet, just get them loose. Now, back off the tensioning screw. This is usually located either on the front of the saw next to the bar or on the side cover itself. Turn it counter-clockwise until the bar slides back toward the drive sprocket. This gives you the slack you need to actually get the new chain over the drum.

Once the side cover is off, take a second to clean things out. Sawdust and bar oil create this nasty, cement-like sludge. If that gunk builds up around the sprocket or inside the oil channels, your new chain is going to wear out in half the time. Use a small flathead screwdriver or a piece of wire to scrape the "groove" of the guide bar. If that groove is clogged, the oil can't reach the chain, and you’ll end up with metal-on-metal friction that destroys the heat treatment of your bar.

Seating the Chain Correctly

Hold the chain by the top loop. Let the bottom hang down. It’s kinda like a necklace that wants to tangle itself. Carefully drape the chain over the drive sprocket first. Make sure the drive links—the pointy parts that look like shark fins—sit snugly in the teeth of the sprocket.

Now, pull the chain forward and slot it into the groove of the bar. This is where people get annoyed. The chain likes to pop out of the groove while you're trying to put the side cover back on.

The Tensioner Pin Trap

Here is the "secret" part of knowing how to install chainsaw chain that separates the experts from the frustrated: the tensioner pin.

On the inside of your side cover (or on the saw body), there is a small metal pin. This pin MUST fit into the small hole on the guide bar. If you bolt the cover down and that pin isn't lined up, you’ll bend the pin or crack the cover. Align the bar so the pin drops into the hole before you even touch the bar nuts. Once it clicks into place, thread the nuts on finger-tight. Don't crank them down yet. If you tighten them now, you won't be able to adjust the tension.

Dialing in the Tension (The "Snap" Test)

Tensioning is an art form. Too loose, and the chain jumps the track. Too tight, and you put massive strain on the crank bearings and the bar nose sprocket.

Lift the tip of the bar up. Keep it lifted while you turn the tensioning screw clockwise. You want to tighten it until the "slop" disappears from the bottom of the bar. The drive links should be fully tucked into the bar groove.

Now, do the snap test. Pull the chain down away from the bar in the middle. It should come out a bit, but when you let go, it should "snap" back into the groove instantly. If it stays hanging, it's too loose. If you can barely pull it out at all, it's too tight. A perfect chain should be able to be rotated around the bar by hand (wear gloves!) with just a little bit of resistance.

👉 See also: The Five Minute Journal App: Is it actually worth your home screen space?

Once you’re happy, tighten those bar nuts down for real. Not "Hulk" tight, but firm.

Why Your New Chain Might Stretch

Brand new chains stretch. It’s not actually the metal stretching; it’s the rivets "seating" into the holes. You might notice that after five minutes of cutting, the chain is sagging again. This is normal.

Stop the saw. Let it cool for a minute. If you tighten a blistering hot chain to "perfect" tension, it will shrink as it cools and potentially snap or damage the internal components. Always check your tension after the first few cuts of the day.

Also, check your oiler. While you're testing the new chain, hold the saw over a stump or a piece of cardboard and rev it. You should see a faint line of oil spraying off the tip. If it’s dry, stop immediately. A dry chain is a dead chain.

Maintenance Beyond the Install

Installing the chain is only half the battle. You have to look at the bar, too. Every time you change or sharpen a chain, flip the bar over. Most bars are symmetrical for a reason. If you always run the bar in the same orientation, the bottom rail will wear down faster because that’s where most of the cutting happens. Flipping it ensures even wear and a longer life for the tool.

If you notice the saw is cutting at an angle—pulling to the left or right—that’s usually a sign that your bar rails are uneven or you’ve sharpened one side of the chain more than the other. No amount of tensioning will fix a bent bar or uneven rails.

📖 Related: Why the Jordan 2 Red White Still Divides the Sneaker World

Actionable Steps for a Successful Cut

- Confirm Orientation: Ensure cutters face the "long way" around the bar tip.

- Clean the Groove: Use a bar tool to scrape out packed-in dust and dried oil.

- Check the Sprocket: If the teeth on your drive sprocket look like "hooks," it's time to replace the sprocket, or it will eat your new chain.

- The 2-Minute Check: After installing and cutting for two minutes, shut down and re-tension.

- Keep it Lubed: Ensure the oil hole on the bar is perfectly clear so the pump can do its job.

Taking ten minutes to do this properly saves you hours of filing and hundreds of dollars in replacement parts. If the chain moves freely by hand and snaps back into the groove when pulled, you're ready to work.