You’ve probably seen the rust-red silhouettes of old mills while driving through Pennsylvania. Most people assume they’re just skeletons of a dead era. But if you pull into the Iron Street facility of Johnstown Wire Technologies, you’ll realize that’s basically a lie. It's loud. It's busy.

They aren't just surviving; they’re actually one of the biggest independent producers of value-added carbon and alloy wire in North America. It’s weird how we talk about "the death of American manufacturing" while a place like Johnstown Wire Technologies in Johnstown, PA, is churning out thousands of tons of product for the automotive and construction industries every single month.

Why Johnstown Wire Technologies Johnstown PA Isn't Your Average Mill

Let’s get one thing straight. This isn't just a place where they melt metal and hope for the best. The facility has roots that go back to the 19th century—specifically as part of the massive Bethlehem Steel empire. When Bethlehem folded, a lot of people thought the Johnstown plant would just crumble into the Conemaugh River. Instead, it spun off, rebranded, and specialized.

What makes them different? Honestly, it’s the "value-added" part. Most commodity mills just make basic wire. JWT does the hard stuff. They handle electrolysis, lead-free galvanizing, and incredibly specific thermal treatments. If you’ve ever sat in a car seat or used a heavy-duty bolt in a construction project, there’s a massive chance the skeleton of that component started as a coil in Johnstown. They aren't just making wire; they’re making the stuff that keeps your world from falling apart.

The Technical Grit: What Happens Inside the Gates

It’s easy to get lost in the jargon of metallurgy, but basically, they take wire rod—which looks like giant spools of thick metal spaghetti—and pull it through dies to make it thinner and stronger. This is called cold drawing. But JWT goes a step further with their "clean steel" practices.

They’re famous for their electro-galvanized products. This isn't just dipping metal in a vat of zinc. It’s a precise chemical process that creates a coating so uniform it’s measured in microns. Why do you care? Because if that wire goes into a bridge cable or a high-tension spring, any tiny imperfection means a catastrophic snap later on.

Breaking Down the Product Line

- CHQ Wire: That stands for Cold Heading Quality. It’s for making fasteners. Think of the bolts holding an engine block together. They have to be perfect.

- Aluminized Wire: This is a big deal for them. It’s wire coated in aluminum to resist corrosion. It’s what you see in chain-link fences that actually last fifty years without turning orange.

- Spring Wire: Not the kind in your ballpoint pen. We’re talking heavy-duty industrial springs that take thousands of pounds of pressure.

The facility itself is huge. It spans over 600,000 square feet. It’s a maze of heavy machinery and overhead cranes that would make a safety inspector's head spin if they weren't so meticulously maintained. You've got to understand that the sheer scale of the equipment is what allows them to hit such tight tolerances. You can't just do this in a garage.

The Ownership Shift: From Aterian to Private Equity

Money talks. In the mid-2010s, Aterian Investment Partners bought the company. Then, more recently, they were acquired by another group. People get nervous when private equity enters the conversation because they usually think "layoffs and liquidation."

But with Johnstown Wire Technologies, the play was different. The investors realized that the US infrastructure is literally rotting. We need wire. We need it for the power grid, for new highways, and for the massive push in domestic car manufacturing. They didn't gut the place; they invested in the "Lead-Free" galvanizing lines to stay ahead of environmental regulations. It was a smart move. It kept them relevant while other mills were getting fined out of existence.

The "Johnstown Factor" and the Local Economy

You can't talk about this company without talking about the city of Johnstown itself. This town has been kicked in the teeth by floods and economic downturns for over a century. Yet, the workforce at JWT is legendary in the industry. These are multi-generational steelworkers.

It’s not uncommon to find a guy on the floor whose grandfather worked the same bays back when it was Bethlehem Steel. That kind of institutional knowledge is impossible to replicate with a training manual. They know how the machines "sound" when they’re running right. It’s a blend of high-tech sensors and old-school intuition.

Addressing the "Ghost Town" Myth

There’s this weird narrative that Pennsylvania’s "Steel Valley" is a museum. It's not. While places like Pittsburgh have pivoted to tech and healthcare, Johnstown has doubled down on specialized niche manufacturing.

If you look at the shipping logs, JWT isn't just sending stuff to Philly or Pittsburgh. They’re exporting. They’re shipping to Mexico, Canada, and all over the Midwest. They’ve managed to stay competitive against cheap overseas imports by focusing on quality and specialized coatings that the massive, low-cost mills in Asia don't want to mess with because the volume is too "small" for them. JWT thrives in that high-complexity, medium-volume sweet spot.

Real-World Impact: Where the Wire Actually Goes

Let’s look at a car. Most people think of the engine or the touchscreen. But look at the headrests. Look at the seat frames. Look at the tiny springs in the suspension. A huge chunk of the domestic "Tier 1" automotive supply chain relies on Johnstown Wire Technologies.

In the construction world, they provide the "reinforcement." When you see a massive concrete parking garage going up, the tensioning wires inside those slabs might have come from PA. It’s the invisible backbone of the American built environment.

Sustainability and the "Green" Steel Pivot

Let’s be real: steelmaking is traditionally dirty. But JWT has been pushing into aluminized coatings which are way more eco-friendly than the old-school lead-bath processes. They’re also heavily involved in recycling. Steel is the most recycled material on earth, and the "rod" they start with is often made from melted-down scrap. It’s a circular economy before that was even a buzzword.

💡 You might also like: Great-West Lifeco Stock: What Most People Get Wrong

What Most People Miss About the Business Model

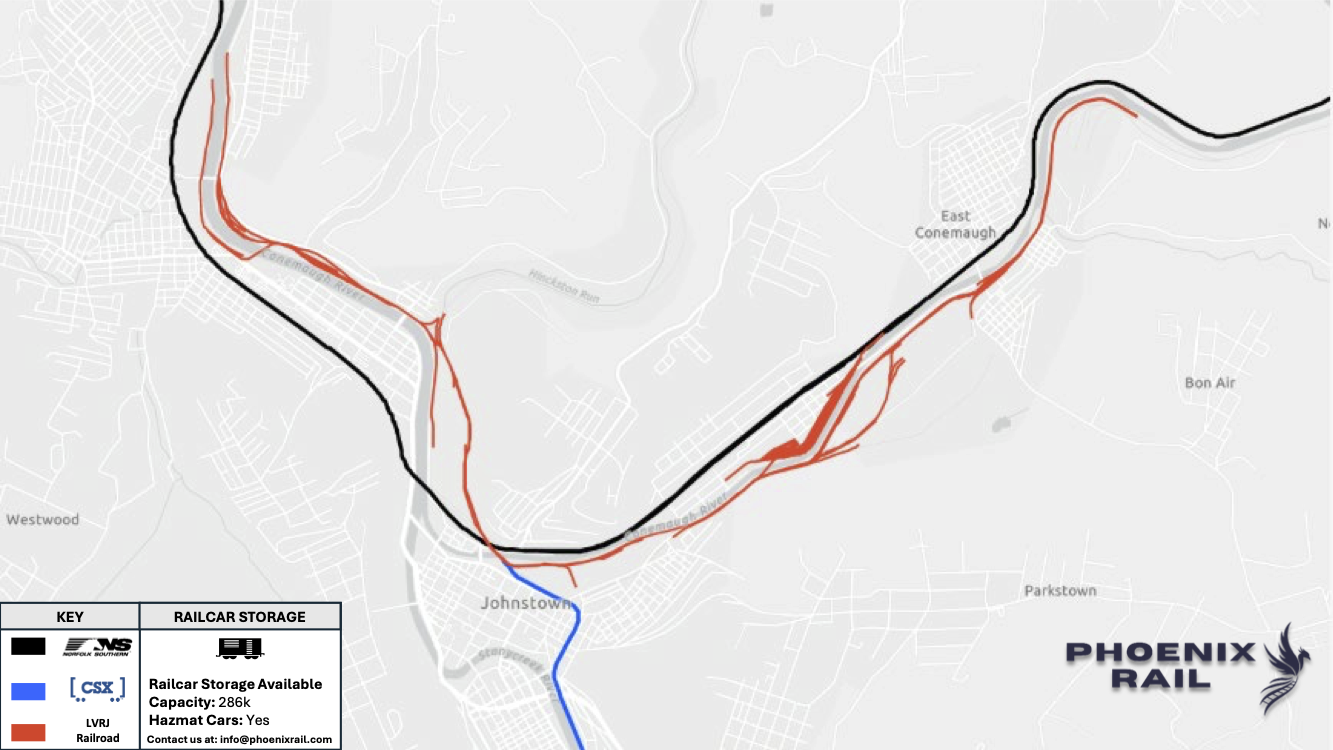

It’s not just about making wire. It’s about logistics. Johnstown is strategically located. You’ve got rail access and you’re close to the major interstates. In a world where "just-in-time" manufacturing is the standard, being able to get a truckload of CHQ wire to an assembly plant in Ohio or Michigan in six hours is a massive competitive advantage.

They also offer "toll processing." This is basically when another company owns the metal but pays JWT to use their fancy machines to clean, coat, or draw it. It’s a genius way to keep the machines running and the revenue flowing even when the price of raw steel is bouncing around like crazy.

Navigating the Challenges

It isn't all sunshine and molten metal. Like everyone else, they’ve struggled with labor shortages. Finding young people who want to work in a loud, hot mill is tough. They’ve had to hike wages and improve benefits significantly to keep the lines moving.

Energy costs are another headache. Running those massive furnaces and electrolytic baths eats up a staggering amount of electricity. When the grid prices spike, the margins get thin. But because they’ve specialized in high-margin "specialty" wire, they can absorb those hits better than a commodity mill making basic rebar.

Actionable Insights for Industry Observers

If you’re looking at the state of American manufacturing through the lens of Johnstown Wire Technologies, here is what you need to understand.

First, specialization is the only way to survive. If you’re making something that anyone can make, you’re going to lose to a factory in a country with lower environmental standards. JWT survives because they do the stuff that’s "too hard" for others.

Second, the "Rust Belt" isn't a monolith. There are pockets of extreme high-tech growth hidden inside these old brick buildings. Don't bet against the institutional knowledge of a Pennsylvania steel town.

Finally, keep an eye on the infrastructure bills. As the US moves to modernize its power grid and bridges, companies like JWT are the first ones to see the order books fill up. They are a "leading indicator" for the health of the broader economy.

Practical Steps for Partners and Clients

- Audit your supply chain: If you’re sourcing wire from overseas to save 5%, calculate the risk of shipping delays and quality failures. Domestic sources like JWT offer "track and trace" quality that prevents massive recalls in the automotive sector.

- Look into Aluminized coatings: If you’re currently using traditional galvanizing for outdoor applications, the aluminized wire coming out of Johnstown offers better long-term corrosion resistance in acidic environments.

- Check the specs: JWT provides detailed metallurgical certs for every coil. This is crucial for ISO-certified manufacturers who need to prove the chemistry of their raw materials.

Johnstown Wire Technologies remains a powerhouse because they didn't try to be everything to everyone. They found the hardest, most annoying wires to make and became the best at it. In an era of digital everything, there’s something reassuring about a place that still makes things you can drop on your foot. It's heavy, it's real, and it's not going anywhere.