You’ve got a mountain of fabric scraps. Admit it. It’s sitting in a bin, or maybe a trash bag, taking up space in the back of the closet because you can’t bear to throw away those linen offcuts or that old duvet cover. Making a fabric rug seems like the perfect "Pinterest-y" solution. But honestly? Most people start these projects and give up by hour three because they realize, too late, that their fabric choice is a nightmare or their technique is destroying their lower back.

It’s not just about braiding rags.

If you want a rug that actually stays flat and doesn't look like a primary school art project gone wrong, you need to understand the physics of tension and the reality of fiber friction. Most tutorials skip the part where they tell you that jersey knit will curl into a tube, while quilting cotton will fray until your living room looks like a lint trap exploded.

The Fabric Rug Reality Check

Before you even touch a pair of scissors, we need to talk about what you're actually walking on. A rug made of silk scraps is a death trap. It’s slippery. A rug made entirely of heavy denim is basically a weapon if you try to wash it in a standard machine.

Expert makers like claire-anne o'brien or the traditionalists at the Rug Hooking Guild of Newfoundland and Labrador will tell you that material consistency is king. If you mix a stretchy t-shirt strip with a stiff upholstery remnant, the rug will buckle. It’s inevitable. The different "give" in the fabrics means one side pulls tighter than the other.

Why cotton is your best friend (usually)

Cotton is predictable. Whether you’re using old bedsheets or calico, cotton has a grip that holds knots and braids in place. If you're going the "shag" route—prodding strips through a mesh backing—cotton stays upright. Synthetic blends like polyester tend to slide out of the holes. It’s frustrating. You’ll find yourself re-threading the same corner six times.

Tooling Up for the Long Haul

Don't use your good dressmaking shears. Please.

Cutting through yards of fabric to create strips will dull a blade faster than you can say "rotary cutter." You need a dedicated rotary cutter and a self-healing mat. If you’re doing a "locker hook" style or a traditional "proddy" rug, you’ll also need a rug hook or a spring-loaded tool.

- Rotary Cutter: Get the 45mm size. The 60mm is overkill for scraps.

- The "Hessian" Factor: If you're using a base, burlap (hessian) is the classic choice, but it sheds. Rug warping or monk's cloth is the professional move.

- Needle and Thread: You’ll need heavy-duty upholstery thread to join your strips. Tying knots creates lumps. Lumps hurt your feet. Just sew the ends together.

How to Make a Fabric Rug That Actually Stays Flat

The biggest struggle with making a fabric rug—especially the braided variety—is the "coiling" phase. You braid three long strips, and then you start sewing the braid into a spiral. This is where the disaster happens.

If you pull the braid too tight as you sew, the rug will bowl. It’ll literally turn into a shallow basket. If you sew it too loosely, it’ll wavy-edge like a lasagna noodle.

You have to work on a hard, flat floor. Not a carpet. Not your lap.

The "Twist and Tuck" Secret

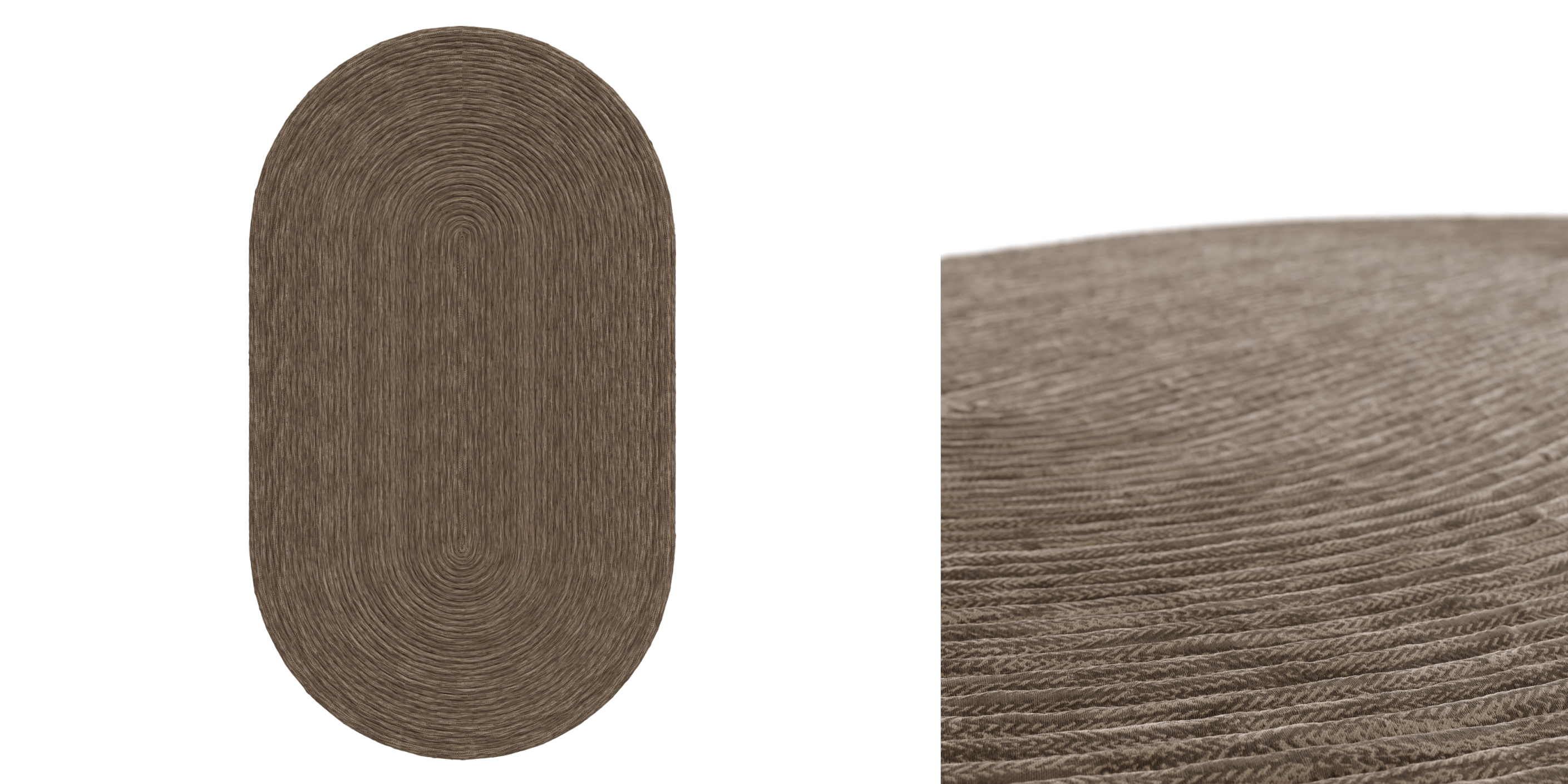

When you’re turning a corner or rounding the curve of an oval rug, you have to "feed" more braid into the outer edge than the inner edge. Think of it like a racetrack. The outer lane is longer. If you don't account for that extra distance by easing the braid in, the tension will pull the center of the rug upward.

📖 Related: Martha Stewart One Pot Pasta: What Most People Get Wrong

The No-Sew Alternative: Proddy and Shaggy Rugs

Maybe you hate sewing. That’s fair. Proddy rugs (or "poked" rugs) were the staple of 19th-century working-class homes in the North of England. You take a piece of burlap, poke two holes, and thread a short strip of fabric through so both ends stick up on the top side.

The friction of the weave holds the fabric in place.

It’s tedious. It’s incredibly slow. But the result is a thick, plush pile that feels amazing. The trick here is density. If you space your strips too far apart, the rug looks "balding." If they’re too close, the rug will become stiff as a board and potentially warp the backing. Aim for a "grid" where the strips support each other but still have room to breathe.

Strips vs. Tubes

If you're using t-shirts, you’re working with "t-shirt yarn" or tarn. When you pull a strip of jersey, it curls into a tube. This is a massive advantage. It hides the raw, messy edges of the fabric inside the curl. If you’re using woven fabric, you have to fold the edges inward manually if you want a clean look, which basically triples your production time.

Honestly? Embrace the fray if you're using wovens. A bit of a "shabby" edge gives it character.

Maintenance: The Part Nobody Likes

You’ve spent 40 hours making this thing. Now someone spills coffee on it.

Handmade rugs are heavy. When they get wet, they get extremely heavy. A 3x5 fabric rug can easily exceed the weight limit of a domestic washing machine once it’s saturated. If you didn’t sew your joins securely, the agitation of a wash cycle will rip the rug apart.

- Spot clean first. Always.

- Vacuum with care. Don't use a beater bar; it’ll snag the loops or pull out the prodded strips.

- The "Snow Clean" method. If you live somewhere cold, toss the rug face down in clean, dry snow, beat it with a broom, and shake it out. It sounds fake, but it’s an old-school technique that works without soaking the fibers.

Nuance in Color Grading

Don't just grab scraps at random. A "scrap rug" can easily look like a pile of garbage if the colors are too chaotic. Try to stick to a "temperature." Use all warm tones (reds, oranges, yellows) or all cool tones. Or, use a "constant"—a single color like navy or white that appears in every third braid. This anchors the design.

It gives the eye a place to rest.

Your Immediate Action Plan

Stop researching and start sorting. Your first step isn't buying a hook; it's auditing your stash.

Separate your fabrics by weight and stretch. Put all the t-shirts in one pile, the denim in another, and the quilting cotton in a third. Pick one pile. Don't mix them for your first project.

Once you’ve picked your pile, cut ten test strips. Each should be about 1 inch wide. Braid them. See how they behave. Does the braid feel sturdy? Does it feel like a limp noodle? This 5-minute test will save you from wasting 20 yards of fabric on a rug that won't survive a week.

Next, find a flat surface where you can leave the project out. Making a rug isn't a "one-evening" hobby. It’s a marathon. If you have to pack it up every night, you’ll never finish it. Set up a station, get a good light, and start your first coil. Focus on keeping that center spiral flat—if the "heart" of the rug is flat, the rest will follow.