You're standing in the lumber aisle at Menards. The smell of sawdust is thick. You see two stacks of wood that look almost identical, but one is labeled "5/4 x 6" and the other is "2 x 6." Most people grab the 2-inch stuff because it looks "beefier." That's a mistake. Honestly, if you're building a residential deck, Menards 5 4 deck boards are usually the superior choice, but there's a weird amount of confusion about what that "5/4" actually means and how it holds up over a humid Midwest summer.

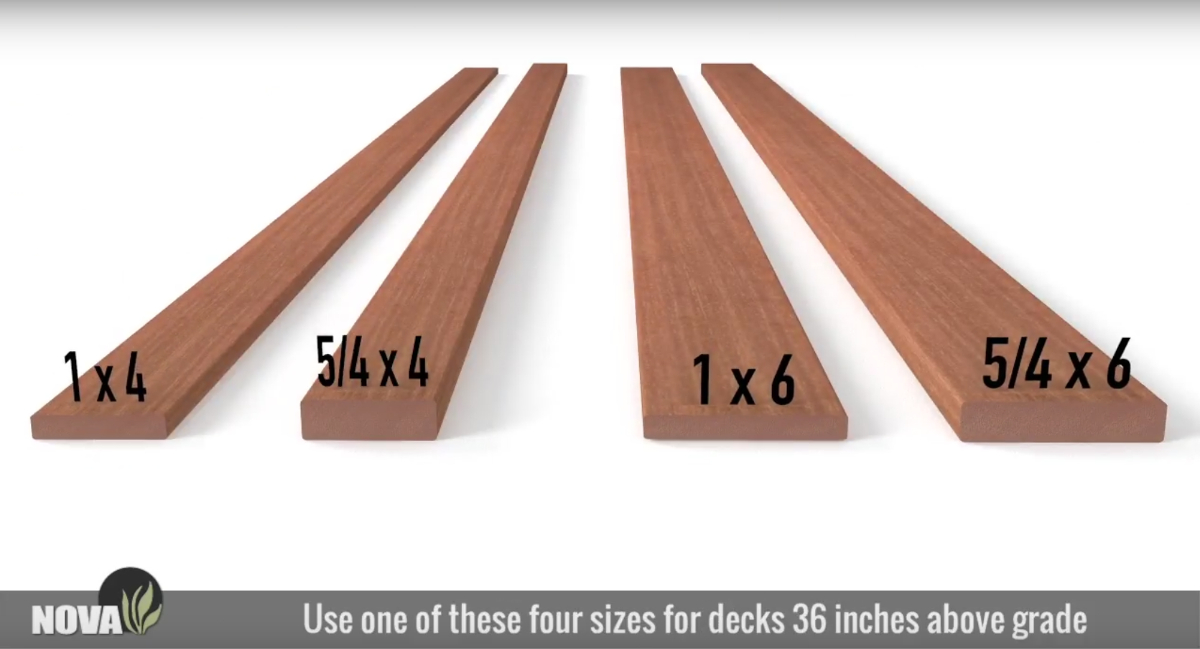

Let's clear the air. In the world of lumber, 5/4 is pronounced "five-quarters." It’s a nominal measurement. After the mill planes and sands it down, you’re left with a board that is exactly 1 inch thick. Compare that to a standard 2x6, which is actually 1.5 inches thick. It sounds like a downgrade, right? Why pay for less wood? Well, it’s about the radius edge and the weight.

Why the Radius Edge on Menards 5 4 Deck Boards Actually Matters

Ever walked barefoot on an old deck and caught a nasty splinter? Or maybe you noticed how water just sits in the cracks of a 2x6 deck? That's why the 5/4 exists. Unlike standard dimensional lumber, these boards come with a "radius edge." This means the corners are rounded off during the manufacturing process.

It’s not just for aesthetics.

🔗 Read more: Estée Lauder Double Wear 2N1: What Most People Get Wrong About This Shade

Because the edges are rounded, water sheds off the surface much faster than it does on a sharp-edged 2x6. When water sits, rot starts. At Menards, you’ll find these primarily in Green Pressure Treated lumber, AC2 CedarTone, or high-end Composite like UltraDeck. The rounded profile also makes the deck feel softer underfoot. It’s the difference between a floor and a platform.

If you use a standard 2x6, the sharp edges eventually curl or "cup." When a 2-inch board cups, it creates a literal pool for rainwater. A 5/4 board is engineered to be a finished surface. It’s designed specifically for the top of your deck, not the structural joists underneath.

The AC2 Factor: Menards’ Secret Sauce

Menards is famous for its AC2 pressure-treated brand. If you’re looking at Menards 5 4 deck boards in the treated section, you’re looking at Micronized Copper Azole (MCA). This is a big deal compared to the old-school CCA (Chromated Copper Arsenate) that was phased out years ago for residential use because it contained arsenic.

AC2 is less corrosive. You won’t see your screws rusting out and snapping off after three years, provided you use the right fasteners. But here is the nuance: not all AC2 is created equal. Menards carries different grades. You’ll see "Premium" and "Standard."

Spend the extra money on Premium.

Standard grade 5/4 boards often have "waney" edges—that’s where the bark was still on the tree, leaving a sloped, missing chunk on the corner of the board. It looks cheap. It feels cheap. Premium boards are generally clearer, with fewer knots and straighter grains. When you’re laying 400 square feet of decking, those knots add up to future cracks.

Ground Contact vs. Above Ground

This is where people get burned. Literally. If you buy the wrong 5/4 board for a low-profile deck, it will rot in five years.

Menards sells two types of treatment levels. One is for "Above Ground" use and the other is for "Ground Contact." If your deck is less than 6 inches off the dirt, or if you have poor ventilation, you must use Ground Contact rated boards. Most 5/4 decking at Menards is rated for "Above Ground" because it’s meant to be the top layer of a raised structure.

Check the tag on the end of the board. If it says "UC3B," it’s for above ground. If it says "UC4A," it’s for ground contact. Using an above-ground board for a ground-level patio is a recipe for a fungal feast. The wood stays damp, the air doesn't circulate, and the treatment isn't concentrated enough to stop the decay.

The Math of Joist Spacing

Don't skip this. You can't just swap 2-inch boards for 5/4 boards without looking at your frame.

Because a Menards 5 4 deck board is thinner (1 inch actual), it has more "flex" than a 2x6. If your joists are spaced 24 inches apart, do not use 5/4 boards. Your deck will feel like a trampoline. It might even break.

For 5/4 decking, your joists should be 16 inches on center. If you want to lay your boards diagonally? You need to move those joists to 12 inches on center. If you ignore this, the "bounce" in the wood will eventually pull the screws out, and the whole thing will feel unstable. I've seen DIYers try to save money by stretching the joist spacing, but they always regret it when the grill starts wobbling every time someone walks by.

Real Talk: The Drying Process

Wood is a sponge. When you buy pressure-treated 5/4 boards from a big-box store, they are often "wet." They’ve been pumped full of liquid preservative and sat in a bundle in the yard.

They are heavy. They are swollen.

If you screw them down tight against each other while they're wet, they look great for about a month. Then the sun hits them. As they dry, they shrink. That tight gap you worked so hard on? It’s now a half-inch canyon that swallows phone chargers and car keys.

🔗 Read more: Braided Bob Box Braids: Why This Low-Maintenance Shortcut is Taking Over

Conversely, if you buy "KDAT" (Kiln Dried After Treatment) boards—which Menards sometimes stocks in specialty sections—they’ve already done their shrinking. You can gap those with a 16-penny nail and they’ll stay that way. For the standard wet stuff, most pros suggest installing them butt-tight. By the time the Michigan or Illinois summer is over, they’ll have shrunk just enough to provide the perfect drainage gap.

Composite vs. Wood: The 5/4 Profile

Menards pushes their UltraDeck and Trex lines hard. These are almost always sold in the 5/4 profile. Why? Because composite material is incredibly dense and heavy. A 2-inch thick composite board would be nearly impossible to work with and would cost a fortune.

If you go the UltraDeck route, pay attention to the "Natural" vs. "Fusion" lines. The 5/4 Fusion boards have a capped surface—a plastic shell that protects the wood-fiber core. The standard 5/4 Natural boards are "uncapped." Uncapped composite is a gamble. It can stain if you drop a burger on it, and it can grow mold in the shade.

Installation Mistakes to Avoid

- Wrong Screws: Don't use drywall screws. Don't even use standard "gold" wood screws. The chemicals in AC2 lumber eat through zinc. You need 3-inch 305 or 316-grade stainless steel screws, or at the very least, high-quality coated deck screws (the green or tan ones).

- The Pith Side: Look at the rings on the end of the board. You want the "bark side up." This is debated, but generally, if a board cups, it'll cup away from the center of the tree. Installing them correctly minimizes the "bowl" effect that catches water.

- End Grain Sealing: Every time you cut a 5/4 board, you expose raw wood that isn't as heavily treated as the surface. Buy a small can of copper naphthenate or a "brush-on" preservative and hit those ends. It takes ten seconds. It adds ten years.

Common Misconceptions

People think 5/4 is "cheap." It's actually a specialized product. In many cases, a premium 5/4 board costs more than a standard 2x6 because of the extra milling required to give it that finished, rounded edge.

Another myth is that you can't sand them. You can. If your deck gets fuzzy or grey after a few years, a light sanding will bring back the color. Just remember that the treatment goes deep, but the "colorant" (like CedarTone) is often just a surface stain. If you sand it, you’ll need to re-stain it.

Your Action Plan for the Lumber Yard

When you head to Menards to pick up your Menards 5 4 deck boards, don't just grab from the top of the pile.

Bring a pair of gloves. You're going to need to dig.

📖 Related: Ceres CA Zip Code: What Most People Get Wrong

Look for "crown." Hold the board up and look down its edge like a telescope. If it bows like a banana, put it back. You want boards that are straight. Check for "heartwood"—that’s the darker, denser wood from the center of the tree. It’s naturally more rot-resistant.

Also, check the moisture. If the board feels like it weighs 50 pounds and is dripping wet, it’s going to shrink significantly. Try to find bundles that have had a little time to breathe, or be prepared to let them "acclimate" in your yard for a few days before you screw them down.

- Measure your joist spacing. If it's 24", buy 2x6 boards or add more joists.

- Choose your grade. Go Premium for the main deck area; save Standard for hidden spots or stairs if you're on a budget.

- Match your fasteners. Use 2-1/2" or 3" coated screws specifically rated for AC2.

- Seal the ends. Don't leave raw cuts exposed to the elements.

- Plan for shrinkage. Install wet boards tight; gap dry boards.

Building a deck is a massive chore. Doing it with the wrong lumber makes it a massive chore you have to do twice. Stick with the 5/4 profile for that professional, "barefoot-friendly" finish, but treat it with the respect that specialized lumber requires.