Walk into any high-end nursery or a massive industrial warehouse, and you’ll see them. Little bits of colored plastic dangling from branches or zip-tied to steel racking. It feels almost prehistoric in an era of augmented reality and blockchain tracking. But honestly? Plastic tags for labeling are basically the cockroach of the organizational world—they survive everything, and they’re arguably the most efficient way to keep a business from spiraling into total chaos.

I’ve seen companies try to go "paperless" and "tagless" by relying entirely on internal GPS or floor markings. It usually ends in a disaster of misidentified parts and lost inventory. There is something fundamentally human about needing a physical marker you can grab, flip over, and read with your own eyes without needing a tablet that’s probably out of battery anyway.

The Material Science of Why We Use Plastic Tags for Labeling

Not all plastic is created equal. If you buy those cheap, brittle tags from a big-box store, they’ll sun-bleach and crack within three months. Real industrial-grade plastic tags for labeling are usually made from High-Density Polyethylene (HDPE) or Polypropylene.

Why does that matter?

Because HDPE is basically indestructible in the face of moisture and most chemicals. It’s what milk jugs are made of, but thickened and UV-stabilized. When you’re tagging outdoor assets—think power lines or irrigation valves—you need a material that won't turn into dust after a summer in the Texas sun.

Polypropylene is the go-to for "living hinges" or tags that need to bend without snapping. If you’ve ever seen a tag that wraps around a cable and snaps into itself, that’s likely what you’re looking at. It has a high fatigue resistance. You can bend it a thousand times, and it just keeps hanging on.

The Problem with PVC Tags

A lot of people reach for PVC because it’s cheap. Don't do that. PVC (Polyvinyl Chloride) is fine for indoor, climate-controlled environments, but it hates the cold. Once the temperature drops below freezing, PVC tags become as brittle as a potato chip. If a worker bumps into one with a forklift or even a heavy sleeve, the tag shatters. Stick to HDPE or specialized polyester composites if your warehouse isn't heated.

Printing vs. Engraving: What Actually Lasts?

You’ve got a few options for putting information on these things. Most people think a Sharpie is enough. It isn't. Even "permanent" ink fades under UV light through a process called photodegradation. If you're using plastic tags for labeling for long-term tracking, you have to think about how the "ink" bonds to the substrate.

Thermal transfer printing is the industry standard. It uses a ribbon—usually a resin or wax-resin blend—that the print head melts onto the plastic. Resin ribbons are the gold standard here. They’re smudge-proof, scratch-resistant, and can handle being wiped down with isopropyl alcohol.

✨ Don't miss: Why is Hooters Called Hooters? The Double Meaning That Built an Empire

Then there’s laser engraving.

This is where the laser actually etches the surface or changes the color of the plastic at a molecular level. It’s expensive. But if you are labeling shut-off valves in a chemical plant, you don't want a label that can "peel" or "fade." You want the information to be part of the tag itself.

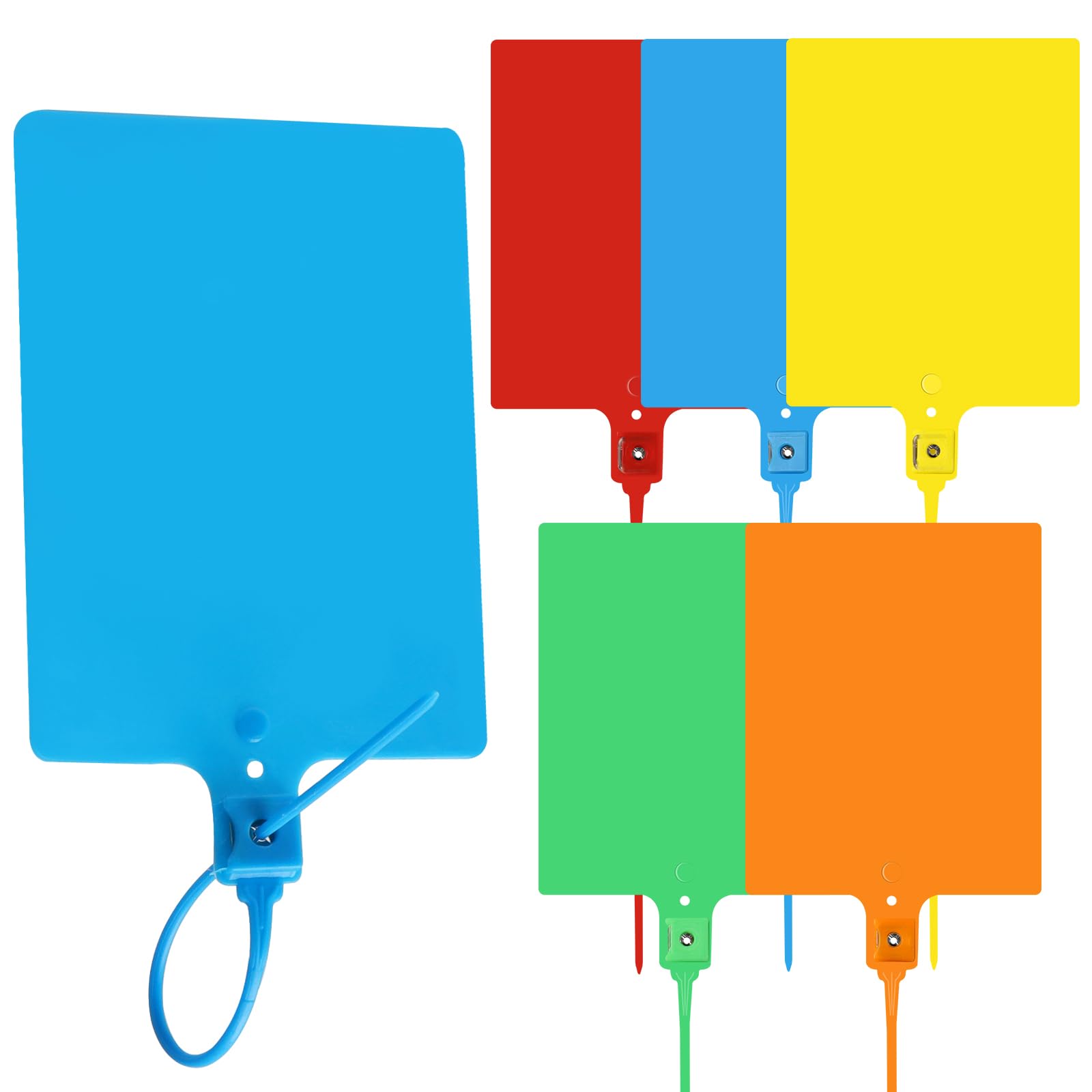

Why Color Coding is Your Secret Weapon

Human brains are wired for fast pattern recognition. We see "Red" and think "Stop" or "Danger" before we even read the word.

In a massive inventory system, using different colored plastic tags for labeling can cut down picking errors by 30% or more. I’ve worked with warehouses where they used a "Traffic Light" system:

- Green tags for "Ready to Ship"

- Yellow for "Quality Hold"

- Red for "Defective/Scrap"

It’s simple. It’s low-tech. It works. You don’t need to train someone for three weeks on a software suite to understand that a red tag means "don't touch this."

The Sustainability Elephant in the Room

Let's be real: we're talking about putting more plastic into the world. In 2026, you can't ignore the environmental footprint. The industry has shifted significantly toward "Post-Consumer Recycled" (PCR) plastics for tagging.

Companies like Avery Dennison and various industrial suppliers now offer tags made from recycled ocean plastics or reground industrial waste. They perform almost identically to virgin plastic, though they might have a slightly grittier texture or a less "pure" white color.

👉 See also: Examples of Letter of Recommendations: Why Most People Get Them Wrong

There's also the rise of biodegradable plastics like PLA (Polylactic Acid). A word of caution: don't use PLA for plastic tags for labeling if they're going outside. PLA is made from corn starch and is designed to break down. If it rains for a week, your tags will start to warp and lose their structural integrity. Keep the eco-friendly stuff for indoor, short-term retail tagging or temporary event management.

Surprising Uses You Probably Haven’t Thought Of

We always think of warehouses, but the most interesting uses for plastic tags are often in the "invisible" sectors.

Take the seafood industry.

When a crate of oysters is harvested, it has to have a tag that stays with it from the boat to the restaurant table. This isn't just for fun—it's federal law in many places for food safety. These tags have to survive saltwater, ice, and rough handling.

Or look at the "Lockout/Tagout" (LOTO) procedures in electrical work. A plastic tag is literally a life-saving device there. It tells other workers that a machine is being serviced and cannot be turned on. In these cases, the tag usually has a reinforced brass eyelet so it can't be accidentally ripped off the padlock.

Myths and Misconceptions About Plastic Labeling

People think digital is always better. "Why not just use a QR code sticker?"

📖 Related: What Tariffs Does China Charge the US: The Real Story for 2026

Stickers peel.

Adhesives fail in high humidity or extreme cold. A plastic tag for labeling that is physically looped through a part or attached with a stainless steel wire isn't going anywhere.

Another myth: All plastic tags are the same.

Incorrect. If you use a tag meant for a clothing boutique in an automotive shop, the oils and greases will dissolve the finish in days. You have to match the "face stock" (the plastic) and the "adhesive" (if there is one) or the "attachment method" to the specific chemicals in your environment.

How to Choose the Right Tag for Your Project

If you’re staring at a catalog of 5,000 different tags, ask yourself these three questions:

- What is the "Pull Strength" required? If it’s hanging on a garment, you need very little. If it’s on a moving engine part, you need a high-mil thickness (usually 10-15 mil or higher) so it doesn't tear at the hole.

- What is the "Lightfastness"? If it's near a window or outdoors, you need UV inhibitors. Look for tags rated for 3-5 years of outdoor use.

- How will you write on it? If you're using a standard pen, you need a "matte" finish. If you're using a thermal printer, you need a specific coating that accepts the ribbon.

Actionable Steps for Implementation

Stop buying generic tags and start thinking about a "Tagging Protocol."

First, audit your current failure points. Are tags falling off? Are they fading? Are people ignoring them?

If they're falling off, switch from plastic ties to stainless steel wire connectors. If they’re fading, stop using markers and invest in a mid-range thermal transfer printer (something like a Zebra or a Brother industrial unit).

Second, standardize your colors. Don't let every department pick their own. Create a master sheet that defines what every color represents across the entire company.

Lastly, look into RFID-integrated plastic tags. These are the "hybrid" solution. They look like a normal plastic tag and have human-readable text on the front, but they have a small chip embedded inside. You get the benefit of a physical tag you can read, plus the ability to scan 50 items at once with a handheld reader. It’s the best of both worlds, and honestly, it’s where most industrial labeling is headed.

Stick to the basics: choose the right polymer, pick a high-contrast color, and ensure the attachment method is stronger than the environment it's living in.