You're standing in the middle of Home Depot. Your hands are covered in grease or sawdust, and you’re staring at a wall of silver and zinc-coated fasteners that all look roughly the same until you get close. Then you see it. That one screw with the weird star shape or the square hole that makes your standard screwdriver look like a relic from the Stone Age. It's frustrating. Honestly, most of us just grab whatever is on sale or whatever "looks" right, but understanding the different kinds of screw heads is basically the difference between a five-minute fix and a three-hour nightmare involving extraction pliers and a lot of swearing.

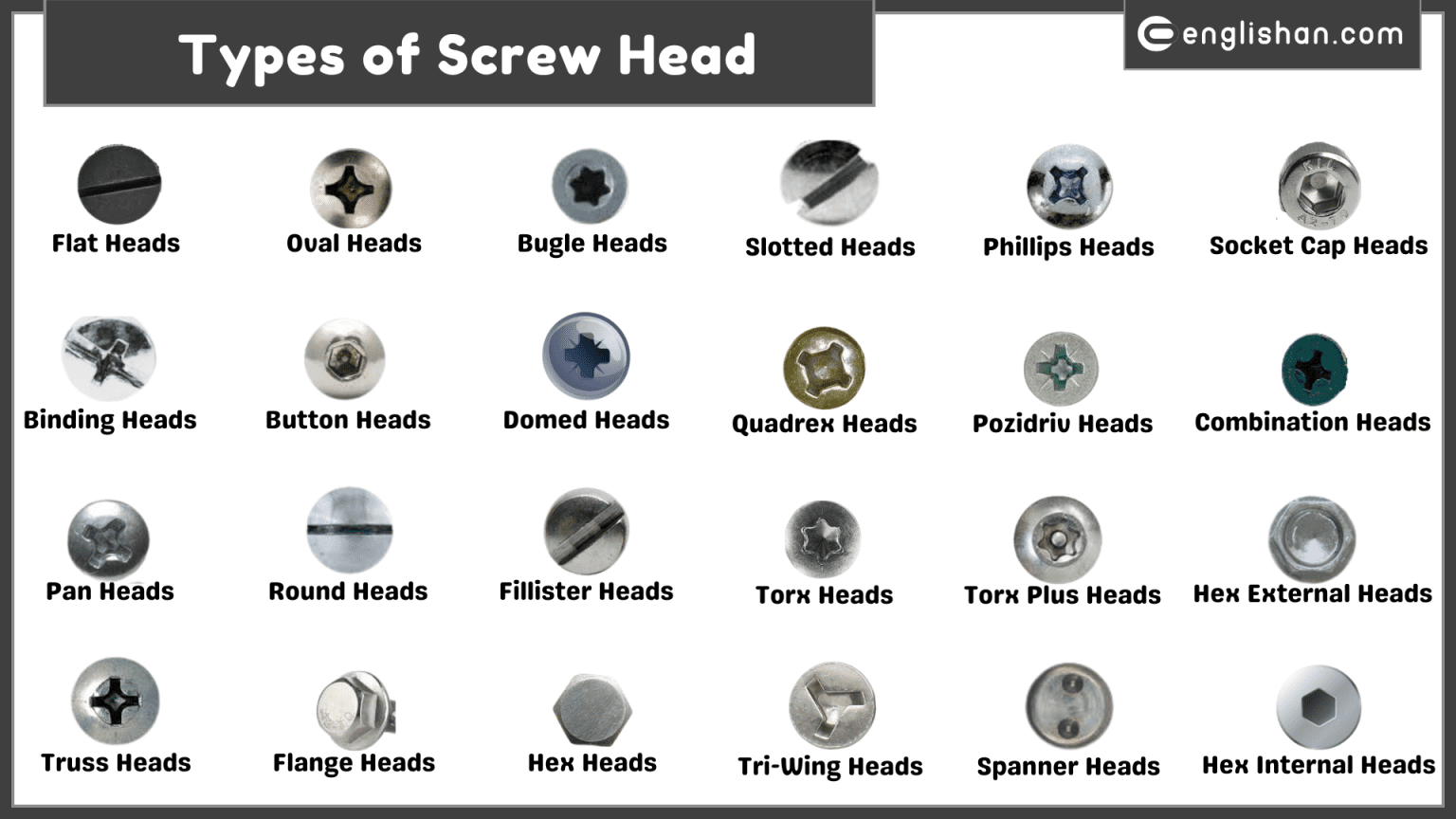

Most people think a screw is just a screw. It’s not. The drive—the part where the tool meets the metal—is engineered for specific torque levels, cam-out prevention, and speed. If you use a Phillips head where you should’ve used a Torx, you’re asking for a stripped head. Once that metal rounds out, you’re done.

The Classics: Slotted and Phillips

Let's talk about the Slotted screw. It’s the oldest. It’s also, quite frankly, the worst. You’ll find them on light switch plates and old furniture. Why do they still exist? Mostly for aesthetics in "vintage" looks or because they are incredibly cheap to manufacture. The flat blade of a screwdriver slips out of a slotted head if you even look at it funny. There is zero "centering" capability. If you are building anything structural, stay away.

Then there is the Phillips head. Henry Phillips popularized this in the 1930s for the Cadillac assembly line. It was a revolution. It’s self-centering, which means the bit naturally settles into the cross shape. But here’s the kicker: it was actually designed to cam out. Back then, power tools didn't have adjustable clutches. To prevent the machines from over-tightening and snapping the screw or damaging the car body, the bit was engineered to slip out of the head once a certain resistance was met. In a modern DIY setting, "camming out" is just another word for "ruining your project."

The Phillips Imposter: Pozidriv

If you've ever bought IKEA furniture or worked on European machinery, you’ve probably encountered the Pozidriv. It looks almost identical to a Phillips but has four additional light tick marks radiating from the center.

- Phillips bits will slip in a Pozidriv screw.

- Pozidriv bits won't even fit properly in a Phillips screw.

Using a Phillips driver on a Pozidriv screw is the #1 cause of stripped screws in flat-pack assembly. The Pozidriv has a flatter internal geometry that allows for much higher torque without the bit "climbing" out of the hole. Look for those tiny "tick" lines. If you see them, put the standard screwdriver away and find a PZ bit.

📖 Related: How to Wash Records Without Ruining the Groove

The Robertson: Canada’s Best Kept Secret

P.L. Robertson was a Canadian who got fed up with his screwdriver slipping and slicing his hand open. In 1908, he patented the square drive. It is, quite simply, one of the best kinds of screw heads ever made. Because it’s a deep square, the screw actually "sticks" to the bit. You can hold the screwdriver horizontally, and the screw won't fall off.

Fisher Body, which made wooden bodies for Ford, loved them. They used thousands. Robertson was a bit of a control freak, though. He wouldn't license the tech to Henry Ford on Ford's terms, so Ford stuck with Phillips. That’s the only reason the square drive isn't the global standard today. It’s purely a century-old grudge. If you’re doing deck work or cabinetry today, you’ll see "Square Drive" everywhere. It’s the pro’s choice for a reason.

The Rise of the Star: Torx and Beyond

If you go to a construction site today, you won’t hear the "clack-clack-clack" of a Phillips bit slipping. You’ll hear the smooth drive of a Torx. Officially called "hexalobular internal driving feature," Torx (or Star drive) is the king of torque.

The six-point star shape allows for a huge amount of surface area contact between the tool and the screw. You almost have to try to strip a Torx screw. Because there is no cam-out force, you don't have to lean your entire body weight onto the drill just to keep the bit seated. This is a lifesaver when you're on a ladder or reaching into a tight corner.

Why Security Screws Are a Different Beast

Ever tried to open a public bathroom stall or a piece of high-end electronics and found a screw with a little "post" in the middle of the star? That’s a Security Torx. It’s designed specifically so people can’t mess with things using standard tools. You need a "Tamper-Resistant" bit with a hole drilled in the center to bypass that post.

It’s a bit of an arms race. As soon as security bits became common in cheap toolkits from Amazon, manufacturers started moving to even weirder shapes like the "Snake Eyes" (spanner) or the "Tri-Wing." The Tri-Wing is famously used by Nintendo and Apple to keep people out of their hardware. It’s not about better torque; it’s about gatekeeping.

Hex and Allen: The Furniture Staples

We can't talk about kinds of screw heads without mentioning the Hex socket. It's the internal version of a standard bolt head. Most people know these as "Allen" screws (Allen is a brand name, like Kleenex).

👉 See also: Birthday Party Bash Games: How to Stop Doing the Same Boring Stuff

The problem with Hex heads in soft metals is that the corners round off easily if the wrench is even slightly the wrong size. Metric and Imperial (SAE) hex keys are just different enough to be dangerous. A 5mm hex key will almost fit a 3/16" hole, but it will have just enough play to ruin the socket if you apply real pressure. If you feel any "wiggle" at all, stop. Check your units.

Specialized Heads You Might Actually Encounter

You might see "Triple Square" screws if you own a German car (Volkswagen or Audi). They look like a 12-pointed star. They allow for incredibly high torque in a small diameter, but they are notorious for filling up with dirt or rust. If you don't clean the head out perfectly before inserting the tool, you will strip it instantly. And since these are usually on vital engine parts or CV joints, stripping one is a genuine disaster.

There’s also the "One-Way" screw. These are the ones you see on security bars over windows. The head is shaped like a ramp. You can turn it in with a flathead screwdriver, but as soon as you try to turn it out, the blade just slides up the ramp. They are "permanent." Removing them usually involves a Dremel, a drill, and a lot of patience.

Matching the Head to the Job

If you're building a deck, use Torx. The pressure-treated lumber is dense, and you’ll be driving hundreds of screws. Your wrists will thank you for the lack of cam-out.

🔗 Read more: Why Most People Get Their Halloween Wreath Wrong (and how to fix it)

For interior cabinetry or furniture where you want a clean look, Robertson (Square) is the way to go. The bit stays on the screw, which is vital when you're trying to hold a heavy cabinet door with one hand and drive a screw with the other.

If you’re doing basic household repairs or hanging a picture, Phillips is fine because you probably already have the tools. Just make sure the bit isn't "rounded" at the tip. A worn-out Phillips bit is a screw’s worst enemy.

A Note on Materials

The head shape matters, but so does the metal. A Grade 8 steel screw can handle way more torque than a cheap zinc-plated one from a "variety pack." If you're working with stainless steel—which is surprisingly soft—you need to be even more careful. Stainless heads strip much faster than carbon steel.

Actionable Steps for Your Next Project

- Audit your bits. Go through your drill driver set. If the tips of your Phillips bits look shiny or rounded, throw them away. They are $1 items that will cause $100 worth of damage to your project.

- Buy a "Security Bit" set. You can find kits with 50+ different "weird" bits for about twenty dollars. It sounds like overkill until the day you need to fix a microwave or a child’s toy and find a weird triangular screw.

- Clean the socket. Before you put a tool into any screw head—especially on a car or outdoor furniture—pick out the gunk with a needle or a wire brush. If the bit doesn't seat all the way to the bottom, it's going to strip.

- Match the size exactly. A #2 Phillips is the standard, but using a #1 in a #2 hole is a recipe for disaster. If it feels loose, it is wrong.

Choosing the right kinds of screw heads isn't just for pros. It's about respecting your own time. Nobody likes spending a Saturday afternoon drilling out a snapped bolt because they used the wrong bit. Get a decent set of Torx and Robertson drivers, and you'll find that DIY suddenly becomes a lot less stressful.