You’re standing in the middle of a big-box hardware store, staring at a wall of shiny chrome. There are sets with 50 pieces and sets with 500 pieces. Some cost $40, while others look like they require a second mortgage. Honestly, picking out a wrench and socket tool set feels a lot like buying a laptop—you’re terrified of getting something that can't handle the job, so you overspend on features you’ll literally never use.

Most people just want to fix a leaky faucet or change their oil.

🔗 Read more: Why Realistic Fiction Books for Teens Still Hit Different in a Digital World

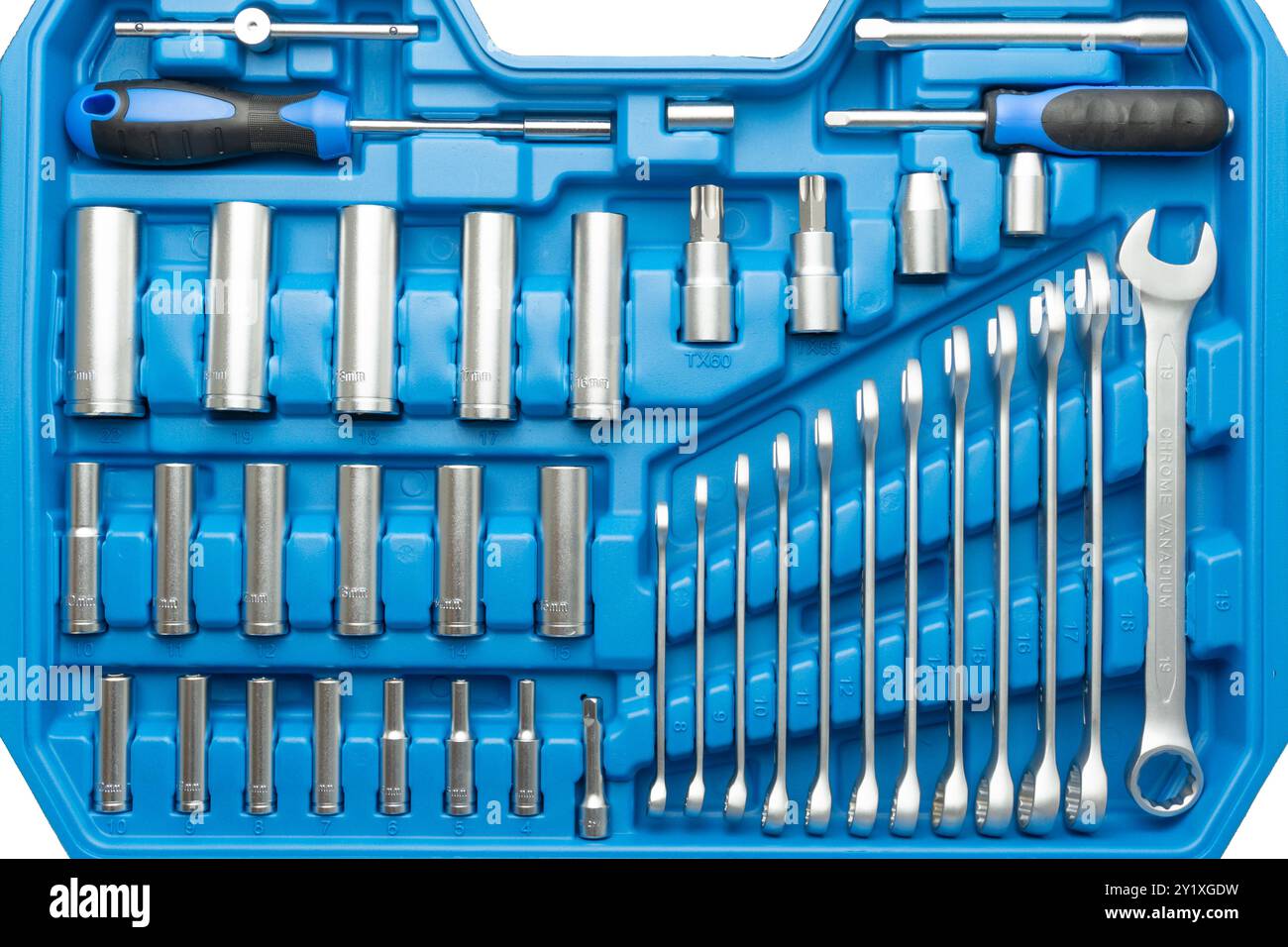

But then you see that massive, three-drawer chest. It’s got deep sockets, shallow sockets, spark plug sockets, and three different sizes of ratchets. It looks professional. It looks like you could rebuild a 1967 Mustang with it. But for a lot of us, that's just dead weight sitting in the garage.

Let's get real about what actually matters when you're turning bolts.

Why the Piece Count is Mostly a Marketing Lie

Companies love to brag about piece counts. "299-piece set!" sounds incredible until you realize that 150 of those pieces are tiny screwdriver bits and plastic wall anchors that have no business being in a "socket set" to begin with. It’s a classic numbers game. You think you’re getting a deal, but you're really paying for filler.

A true, high-quality wrench and socket tool set should focus on the sockets and the wrenches. Period. When you're looking at a kit, ignore the total number on the box. Instead, look at the size runs. Does it skip sizes? Cheap sets often skip the 15mm or the 18mm. You won’t notice it in the store. You’ll only notice it on a Sunday afternoon when your car’s suspension is halfway apart and the one bolt you need to move is—you guessed it—an 18mm.

Missing sizes are the bane of any DIYer’s existence.

Standardization is also a bit of a mess. You have SAE (inches) and Metric (millimeters). If you own a modern car, even a Ford or a Chevy, you’re mostly using metric. American manufacturers switched over years ago for global supply chain reasons. If you’re working on a lawnmower from the 90s or doing home plumbing, you’ll still need those SAE sizes. Buying a set that tries to do both perfectly often means you get a mediocre version of each.

The Ratchet: The Heart of the Whole Operation

The ratchet is the tool you actually hold. It’s the interface between your hand and the machine. If the ratchet feels like garbage, the whole experience is going to be miserable.

There’s this thing called "swing arc." It basically means how far you have to move the handle before the internal gears "click" and grab the next tooth. Cheap ratchets often have 36 or 48 teeth. This means you have to move the handle a long way. If you’re shoved under a sink or reaching into a cramped engine bay, you might not have that much room. You’ll move the handle, it won't click, and you’ll realize you’re effectively stuck.

Modern, high-end ratchets from brands like Snap-on or even the upgraded lines from Harbor Freight (like Icon) use 72-tooth or 90-tooth mechanisms.

It feels buttery smooth. It works in tight spots. It’s worth the extra twenty bucks.

Chrome vs. Impact: Don't Mix Them Up

This is a safety thing that people mess up all the time. Most wrench and socket tool set options come with chrome-plated sockets. They look pretty. They’re easy to wipe clean. But they are brittle. If you get a wild hair and decide to use your chrome sockets with a power impact wrench, they can literally shatter.

I've seen it happen. Steel shards everywhere.

Impact sockets are matte black. They’re made of chrome molybdenum steel, which is "softer" in a way—it’s designed to flex under the hammering of an impact gun. If you’re just using a hand ratchet, chrome is fine. If you’re buying a cordless impact wrench to swap your winter tires, go buy the black sockets.

The Great Wrench Debate: Fixed vs. Ratcheting

A standard combination wrench has one open end and one "box" end. It’s simple. It never breaks. It’s been the standard for a century.

But then there are ratcheting wrenches.

GearWrench basically revolutionized the DIY market with these a couple of decades ago. They are amazing for speed. You don't have to lift the wrench off the bolt every time you turn it. However, they have a weakness: the head is thicker. If you’re trying to get a nut off a bolt that’s tucked right against a firewall, a ratcheting wrench might not fit.

That’s why a solid wrench and socket tool set usually includes a mix of both, or at least a very high-quality set of standard combination wrenches. You need that slim profile for the nightmare jobs.

👉 See also: Why no cook christmas desserts are actually better than baking

Six-Point Sockets Will Save Your Life (Or at Least Your Sanity)

You’ll see two types of socket interiors: 6-point and 12-point.

12-point sockets are easier to slip onto a bolt because there are more angles of entry. They’re great for light-duty work or specialized fasteners. But if you have a rusted, stubborn bolt, a 12-point socket is a rounded-off-bolt factory. It only grips the very corners of the fastener.

A 6-point socket grips the flat sides of the bolt. It’s much harder to slip. If you’re a beginner, always look for a 6-point wrench and socket tool set. It is much more forgiving and significantly less likely to ruin your hardware.

The "Off-Corner Loading" Secret

High-end brands like Wright Tool or Proto talk a lot about "off-corner loading." Basically, the inside of the socket isn't a perfect hexagon. The corners are slightly recessed. This ensures the pressure is applied to the meat of the bolt head, not the fragile tips of the corners. Even mid-tier brands like Tekton or GearWrench do this now. It’s a small detail that makes a massive difference when you’re dealing with a bolt that hasn’t been moved since the Clinton administration.

Organizing the Chaos

Let’s talk about the case. Most molded plastic cases are terrible. You open them upside down once, and 200 pieces of steel go flying across your driveway. You’ll spend the next hour playing the world’s most frustrating game of "Match the Size."

Look for a set with a latch that actually locks. Or, better yet, do what the pros do: ditch the plastic case and buy socket rails.

Rails keep everything in a line. You can see exactly which size is missing. If there’s an empty spot on the rail, you know you left that 10mm socket on the radiator shroud.

Maintenance Most People Ignore

Tools are made of steel. Steel rusts. Even "stainless" or chrome-plated tools can pit and corrode if they’re left in a damp garage. Every now and then, just wipe them down with a rag that has a little bit of WD-40 or light machine oil on it.

And for the love of all things holy, stop using your ratchets as hammers.

I know it’s tempting. You’re right there, the bolt is almost in, it just needs a little tap. Don't do it. The internal gearing of a ratchet is precise. Hammering on it can misalign the pawls, and the next time you put real pressure on it, the gear will slip, and you’ll bash your knuckles into the nearest sharp piece of metal.

How to Actually Choose Your Set

If you're overwhelmed, follow this logic:

- Identify your primary use case. Are you fixing a bicycle or a diesel truck? Bicycles need small, 1/4-inch drive sets. Trucks need 1/2-inch drive sets with long breaker bars.

- Check for "No-Skip" sizing. Ensure the set includes every millimeter from 6mm to 19mm without skipping.

- Feel the ratchet. Go to a store. Click it. Is it loud and clunky? Or does it feel like a Swiss watch? Choose the watch.

- Check the warranty. Brands like Craftsman, Husky, and Kobalt became famous because you could walk into a store with a broken tool and walk out with a new one. That's still a huge value.

Choosing a wrench and socket tool set isn't about owning the most tools; it's about owning the right ones. You don't need a 400-piece master mechanic's kit to fix a loose chair or change a car battery. You need a solid, 50-to-80 piece set that covers the basics with high-quality steel and a smooth ratchet.

Stop looking at the piece count. Start looking at the build quality. Your knuckles will thank you later.

Actionable Next Steps

- Inventory your current fasteners: Check your car or common household items. If everything is metric, don't waste money on a "50/50" split set where half the tools will never be used.

- Prioritize the 3/8-inch drive: This is the "Goldilocks" size. It's strong enough for most automotive work but small enough for household repairs.

- Invest in a "Breaker Bar": If you're doing car work, don't use your ratchet to loosen stuck bolts. Buy a 20-inch solid steel breaker bar. It's cheap, and it saves your expensive ratchet from internal damage.

- Get a magnetic parts tray: While you're buying your tools, grab a $5 magnetic tray. It keeps the nuts and bolts you remove from disappearing into the void.