Everyone wants to be like Toyota. Seriously. For decades, business consultants have swarmed manufacturing floors with stopwatches and clipboards, trying to "lean out" processes by copying exactly what they saw in Japan. They grabbed the kanban boards. They obsessed over andon lights. They mapped every single value stream until their eyes bled. And yet, most of these companies stayed exactly the same. They saw a temporary spike in productivity, sure, but then it plateaued or, worse, slid back into the old, messy way of doing things.

Why?

Because they were looking at the solutions, not the thinking that created them. This is where Toyota Kata Mike Rother changed the game. When Rother published his research after years of studying Toyota’s internal management style, he basically told the Western business world they’d been doing it all wrong. He realized that the "tools" of Lean—the stuff you can see—are just the results of a deeper, invisible habit. He called these habits "Kata."

If you’re trying to fix a business by just copying tools, you’re like someone trying to become a pro athlete by wearing the same shoes as LeBron James. It doesn't work that way. You need the practice. You need the routine.

The Invisible Side of Lean

Most people think of Lean as a toolkit. You’ve got your 5S, your Kaizen events, and your Six Sigma charts. But Rother’s research into Toyota revealed something way more subtle. He found that Toyota wasn't just "doing" Lean; they were practicing a specific way of thinking every single day.

He broke this down into two main routines: the Improvement Kata and the Coaching Kata.

It’s about the "how" of management. Most managers are taught to be "problem solvers." Something breaks, they fix it. Done. But in the world of Toyota Kata Mike Rother describes, the manager’s job isn't to fix the problem. Their job is to develop the person who fixes the problem. That’s a massive psychological shift. It's the difference between giving a man a fish and teaching him how to navigate a complex, ever-changing ocean where the fish keep moving.

Toyota’s success doesn't come from their assembly line. It comes from their ability to handle the "Grey Zone"—the space between where they are now and where they want to be. Most companies freak out in the Grey Zone. They want a roadmap. They want a 12-month plan with milestones. Toyota knows that roadmaps are lies because the world changes too fast. Instead, they use Kata to navigate through the fog.

Breaking Down the Improvement Kata

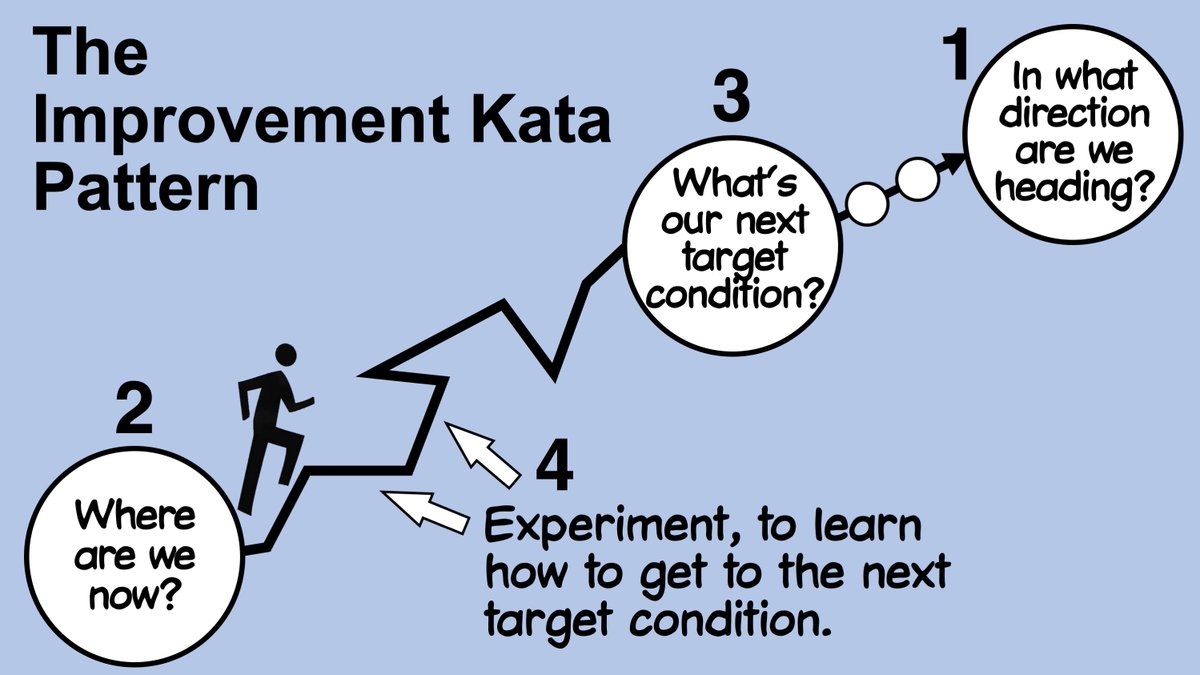

The Improvement Kata is a four-step process. It sounds simple. It’s actually incredibly hard to do consistently.

First, you have to understand the direction. This isn't just a "vision statement" that sits in a dusty frame in the lobby. It’s a challenge. Usually, it’s something that seems impossible right now.

Then, you grasp the current condition. This is where people get lazy. They look at reports. They look at spreadsheets. Rother argues you have to go to the gemba—the actual place where the work happens. You need hard data, not "I think" or "generally." How many seconds? How many defects? What is the actual process, not what the manual says it is.

The third step is establishing the next target condition. This is a small, bite-sized goal on the way to the big challenge. It’s usually only one to four weeks away.

Finally, you conduct experiments. This is the PDCA (Plan-Do-Check-Act) cycle. You don't know the answer, so you try something. You fail. You learn. You try again. It’s scientific thinking applied to the messy reality of a factory floor or an insurance office.

Why Coaching Kata Is the Missing Link

You can’t just tell people to "go experiment." They’ll get scared. They’ll worry about getting fired if an experiment fails. This is why the Coaching Kata is the secret sauce in the Toyota Kata Mike Rother methodology.

The coach (the manager) uses a specific set of five questions to guide the learner.

👉 See also: Why Today Stock Market Closed: The Real Reason Behind the Trading Halt

- What is the Target Condition?

- What is the Actual Condition now?

- What obstacles do you think are preventing you from reaching the target condition? Which one are you addressing now?

- What is your next step (experiment)? What do you expect to happen?

- How quickly can we go and see what we have learned from taking that step?

Notice something? The manager isn't giving advice. They aren't saying, "Hey, try moving that rack over there." They are asking questions that force the learner to think.

It’s basically neural programming. By repeating these questions every day, the manager is literally rewiring the employee’s brain to think scientifically. Over time, the employee stops reacting emotionally to problems and starts looking at them as experiments. That is how you build a "culture of continuous improvement." You don't build it with posters; you build it with daily, boring, repetitive practice.

The Problem With "Results-Only" Management

We live in a world obsessed with KPIs and quarterly results. If you hit your numbers, you’re a hero. If you don't, you’re in trouble.

Rother argues that this focus on results actually kills long-term success. Why? Because it encourages people to cheat the system. If you tell a team they must hit a 95% efficiency rating or lose their bonus, they will find a way to make the numbers look like 95%, even if the process is falling apart. They’ll hide defects. They’ll skip maintenance.

In the Kata model, the process is what matters. If you follow the Improvement Kata, the results will come. It’s like a basketball coach. If the coach only looks at the scoreboard, they aren't helping the players. If the coach focuses on the players' footwork, their shooting form, and their defensive positioning, the scoreboard takes care of itself.

Reality Check: Kata is Hard

Let’s be honest. Most companies that try to implement the ideas in Toyota Kata Mike Rother's book quit within six months.

It’s tedious. It requires managers to actually spend time with their teams instead of sitting in meetings all day. It requires humility from leaders who are used to having all the answers. In a traditional hierarchy, the boss is the smartest person in the room. In a Kata organization, the boss is the one asking the most questions.

There's also the "fake Kata" trap. I’ve seen companies where managers carry around a little card with the five questions, but they ask them like robots. There’s no genuine curiosity. They’re just checking a box. "Okay, question one, what's your target? Great. Question two... okay, hurry up, I have a meeting." That’s not Kata. That’s just another layer of bureaucracy.

Real Kata requires a psychological safety net. People have to feel safe saying, "I don't know what will happen if I try this, but I'm going to find out." If your company culture punishes failure, Kata will die on the vine.

The Impact on Modern Leadership

Rother’s work hasn't just stayed in the world of manufacturing. You’ll find Kata being used in software development (Agile and DevOps love this stuff), healthcare, and even education.

It’s essentially a framework for dealing with uncertainty. And if the last few years have taught us anything, it’s that the world is incredibly uncertain. The old way of "command and control" is too slow. By the time a problem reaches the top of the chain and a decision comes back down, the situation has already changed.

By pushing the "thinking" down to the front lines, organizations become way more agile. They become a collection of thousands of little sensors, all experimenting and learning simultaneously. That is a competitive advantage that is almost impossible to beat.

Practical Steps to Start Using Toyota Kata

If you want to move past just reading about it and actually start doing it, you have to start small. Don't try to roll this out to the whole company. You'll fail.

Pick one pilot area. Choose a process that is stable enough to measure but has a clear problem. Find a "Learner" and a "Coach."

Define the challenge. Make it something that scares you a little bit. If you’re currently at 70% quality, maybe the challenge is 99% in six months.

Establish a daily rhythm. This is the most important part. The coaching cycle should happen every single day. Even if it’s only for 10 minutes. The frequency is more important than the duration. You are building a habit. If you do it once a week, it’s just a meeting. If you do it every day, it becomes a way of life.

📖 Related: Saudi Riyal to PKR: Why Most People Get the Exchange Rate Wrong

Focus on one obstacle at a time. Most people try to fix everything at once. They have a list of 20 things wrong. Pick one. The smallest one. Fix it. Then move to the next. This prevents burnout and keeps the momentum going.

Document the learning. Keep a "Learner’s Storyboard." This isn't a fancy digital dashboard. Often, a physical board with hand-drawn graphs is better. It shows the evolution of the thinking. It tracks what you expected to happen versus what actually happened. That gap—the difference between expectation and reality—is where the learning lives.

Find your own "Second Coach." If you are coaching a learner, who is coaching you? Coaching is a skill that needs to be practiced too. In the Toyota model, every coach has a coach. This ensures that the questions stay sharp and the focus stays on the process, not just the results.

The beauty of Toyota Kata Mike Rother's work is that it’s not a secret recipe. It’s out there for anyone to use. But it requires a level of discipline that most organizations simply aren't willing to commit to. They want the magic pill. They want the "Toyota Results" without the "Toyota Work." If you're willing to do the work, to practice the Kata until it becomes second nature, you'll find that you aren't just improving your business; you're building an organization that is literally designed to learn.

That is the only way to survive in the long run. Forget the tools. Focus on the habits. The rest will follow.

Actionable Next Steps

- Read the book: Start with Toyota Kata: Managing People for Improvement, Adaptiveness and Superior Results. It's the foundation for everything mentioned here.

- Identify your Gemba: Go to the place where work happens today. Don't speak. Just watch for 30 minutes. Note the difference between what you thought happened and what actually happens.

- Draft your first 'Five Questions' card: Keep it in your pocket. Try using those specific questions in your next one-on-one meeting, even if you aren't doing a full "Kata" implementation yet.

- Set a 2-week Target Condition: Instead of a quarterly goal, ask your team what one specific, measurable thing you can change or achieve in exactly 14 days.