Drive down Highway 87 toward the Gulf and you can't miss it. The skyline glows. It’s a massive, tangled web of steel and steam that basically keeps a huge chunk of the American economy moving, even if most folks just see it as a background for a blurry car photo. We’re talking about the Valero Port Arthur Refinery. It’s not just some local plant. Honestly, it’s one of the most sophisticated pieces of engineering on the planet, but there’s a lot of noise and misinformation about what actually happens behind those fences.

People think "refinery" and imagine a giant stove boiling oil. Simple, right? Not even close.

The Port Arthur facility is a beast. It’s sitting on the Taylor Bayou, right in the heart of the "Energy Museum" that is Southeast Texas. While everyone talks about the massive Motiva plant next door, Valero’s site is the one that often sets the pace for high-complexity processing. It’s been around since the early 1900s—starting as a tiny Gulf Oil operation—but today, it’s a high-tech fortress capable of turning the "dirtiest" crude oil into the high-grade fuel in your tank.

Why the Valero Port Arthur Refinery is the "Swiss Army Knife" of Oil

Most refineries are picky eaters. They want light, sweet crude—the easy stuff. But Valero Port Arthur is basically the guy who can eat anything at the buffet. Because of its massive investment in coking units and hydrocrackers, it can take heavy, high-sulfur "sour" crude from places like Canada or South America and strip out the junk.

It’s about complexity. In the industry, we talk about the Nelson Complexity Index. Port Arthur ranks incredibly high.

Why does this matter to you? Because it stabilizes prices. When there’s a geopolitical mess and the "good oil" gets expensive, this refinery just switches gears. It takes the cheap, sludge-like oil and uses extreme pressure and heat to crack those molecules apart. You get the same gasoline at the end, but the refinery saved a fortune on raw materials. That efficiency is basically why Valero stays so competitive in the global market.

The Hurricane Problem: It’s Not Just About Rain

Living on the Texas coast is a gamble. You’ve got the heat, the humidity, and then there’s the big one: hurricane season. For the Valero Port Arthur Refinery, a storm isn't just a day off. It's a logistical nightmare that can ripple through the entire U.S. gas market.

When Harvey hit in 2017, the rain was biblical. Port Arthur was underwater.

Shutting down a refinery isn't like turning off a light. It’s a multi-day process of cooling down units that operate at nearly $1,000$ degrees Fahrenheit. If you do it too fast, the metal shrinks and cracks. If you do it too slow during a flood, you risk fires or chemical leaks. Valero has spent hundreds of millions on "hardening" the site—raising critical equipment, improving drainage, and building backup power systems that can survive a Category 4 hit. They’ve realized that being a giant means nothing if you’re a giant with wet feet.

The Massive Scale of Production (By the Numbers)

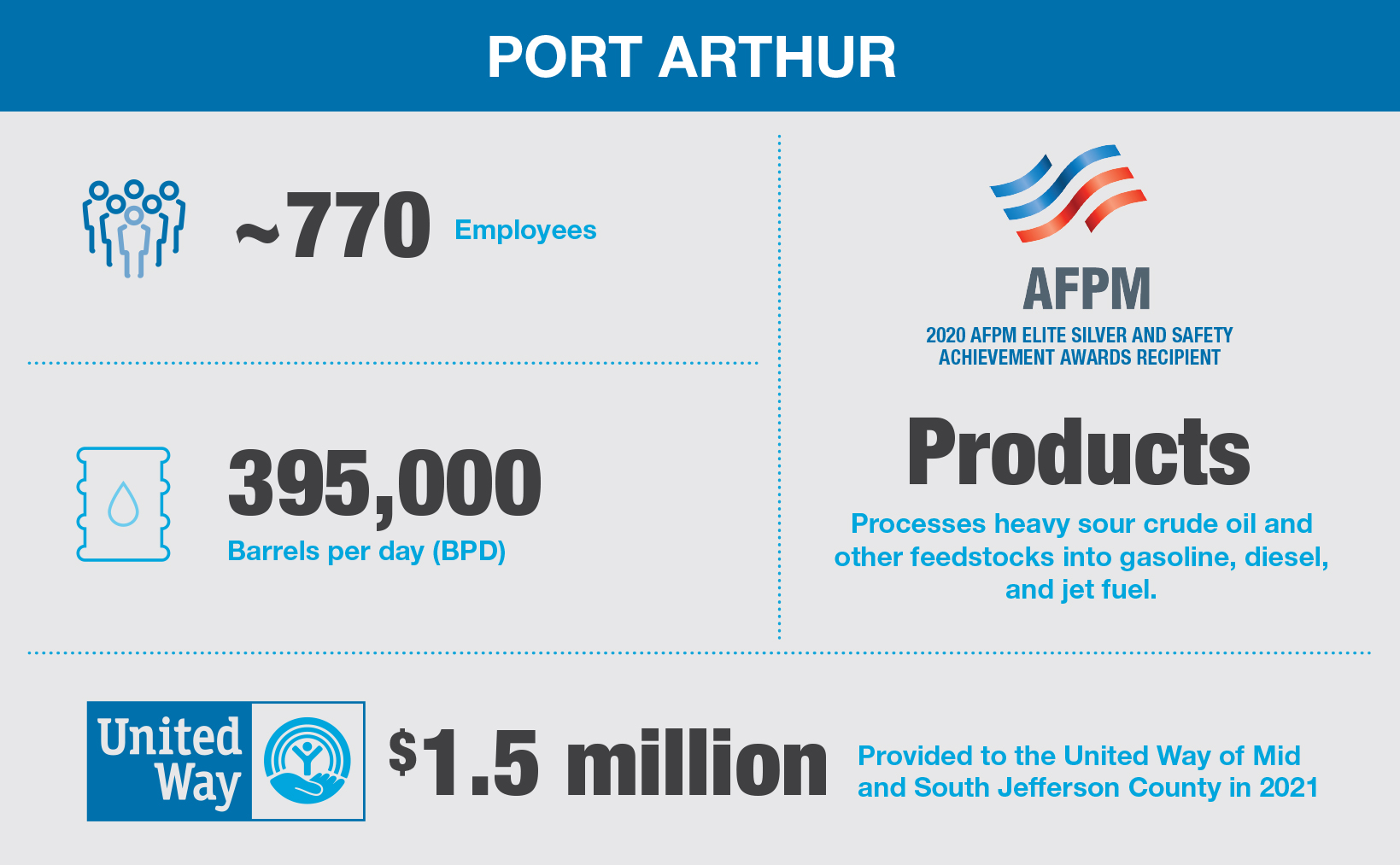

Let’s get into the weeds for a second. The throughput here is staggering. We are talking about a capacity of roughly 395,000 barrels per day.

Think about that.

A barrel is 42 gallons. Every single day, nearly 16 million gallons of product are flowing out of this one spot. It’s not just gasoline, though. That’s a common misconception. They’re cranking out:

- Ultra-low sulfur diesel (the stuff that keeps semi-trucks moving).

- Jet fuel for the big hubs in Houston and Dallas.

- Petrochemical feedstocks that eventually become your phone case or your sneakers.

It’s a 24/7/365 operation. There are thousands of miles of pipe within the facility. If you laid them end-to-end, you’d probably reach across several states. The sheer density of the infrastructure is why the maintenance "turnarounds"—those periods where they shut a unit down to fix it—cost hundreds of millions of dollars and require thousands of extra contractors.

✨ Don't miss: Rupiah to PHP Peso: What Most People Get Wrong About the Exchange Rate

What People Get Wrong About Emissions

Look, no one is saying a refinery is a botanical garden. It’s heavy industry. But the idea that it’s the same "smoke and mirrors" operation from 1950 is just wrong. Valero has been under intense pressure from the EPA and local groups like the Lone Star Legal Aid and various environmental advocates.

They've had to adapt.

The refinery uses massive "scrubbers" and Flare Gas Recovery Systems. Instead of just burning off excess gas (that big flame you see at night), they try to capture it and reuse it as fuel for the plant’s own heaters. It’s a "waste not, want not" approach that also happens to keep the regulators off their backs. Is it perfect? No. There are still "exceedance events" during startups and shutdowns. But the tech today compared to twenty years ago? It’s night and day.

The Economic Engine of Jefferson County

If the Valero Port Arthur Refinery disappeared tomorrow, Port Arthur would be a ghost town. Period.

It’s one of the largest taxpayers in the county. The "Valero Benefit" isn't just the paychecks for the 800+ full-time employees. It’s the "multiplier effect." It’s the local welding shops, the safety equipment suppliers, the catering companies that feed the crews during a turnaround, and the hotels that fill up with specialized technicians from across the country.

Valero also pours money into the local United Way and Lamar State College-Port Arthur. They basically fund the programs that train the next generation of operators. It’s a symbiotic relationship, though sometimes a tense one. The local community deals with the traffic and the noise, but in exchange, they get a level of economic stability that most small American cities would kill for.

The Shift Toward "Renewables" inside an Oil Giant

This is the part that surprises people. Valero is actually one of the world’s largest producers of renewable diesel.

While the Port Arthur site is primarily a crude oil refinery, the company’s overall strategy has shifted. They are looking at how to integrate lower-carbon fuels into the mix. There’s constant talk about carbon capture projects along the Gulf Coast, where the CO2 emitted from the refining process is captured and pumped underground into old salt domes. It’s expensive, and the tech is still scaling, but Port Arthur is a prime candidate for these kinds of "green-ish" upgrades because the infrastructure is already there.

Safety: The "Culture" vs. The Reality

You can't walk ten feet inside the gate without seeing a safety sign. It’s a religion there. After the 2005 BP Texas City explosion (different company, same region), the entire refining industry had a "come to Jesus" moment.

At Valero Port Arthur, everything is about "Process Safety Management."

They use automated sensors that can detect a gas leak long before a human nose could. They have their own elite fire department on-site. The workers wear FRCs (Flame Resistant Clothing) even when it's 105 degrees outside. But even with all that, the risk is never zero. Working there is a high-stakes job. You’re dealing with high pressures, explosive gases, and heavy machinery. That’s why the pay is so high—you aren't just paying for their time; you’re paying for their constant vigilance.

Logistics: How the Oil Moves

How does the oil even get there? It’s not just trucks.

- Pipelines: A hidden map of veins underground bringing oil from the Permian Basin and the Strategic Petroleum Reserve.

- Marine Terminals: Huge tankers dock at the Port of Port Arthur, unloading millions of barrels at a time.

- Rail: The "rolling pipeline" brings in heavy crude that might not flow well in traditional pipes.

Once it's refined, the product doesn't just sit there. It gets pumped into the Colonial Pipeline system, which is basically the artery that feeds the entire East Coast. If Valero Port Arthur has a major hiccup, people in New York and Georgia feel it at the pump three days later.

Actionable Insights for the Future

If you're looking at the Valero Port Arthur Refinery as an investor, a job seeker, or just a concerned citizen, here is what you actually need to watch:

- Monitor the Crack Spread: This is the difference between the price of crude oil and the price of the finished products. When the crack spread is high, Valero is printing money. When it narrows, things get tight.

- Watch the EPA "Risk Management Plan" Updates: Federal regulations are tightening in 2025 and 2026. Keep an eye on how much Valero has to spend on new emissions tech; it’ll tell you how long they plan to keep specific units running.

- Keep an Eye on the Port Arthur LNG Boom: The area is becoming a hub for Liquefied Natural Gas. This creates competition for labor. If you’re a welder or an operator, your value in Port Arthur just went up because you have more options than just the refineries.

- Track Hurricane Readiness: If you live in the area, Valero’s "flare status" is often a better indicator of an approaching storm's severity than the local news. If they start a controlled shutdown, it’s time to pack your bags.

The reality is that we are in an energy transition, but we aren't "there" yet. The world still runs on the products coming out of the Valero Port Arthur Refinery. It’s a massive, complicated, loud, and essential part of the American machine. It’s not going anywhere anytime soon, but it is changing—one pipe and one permit at a time.