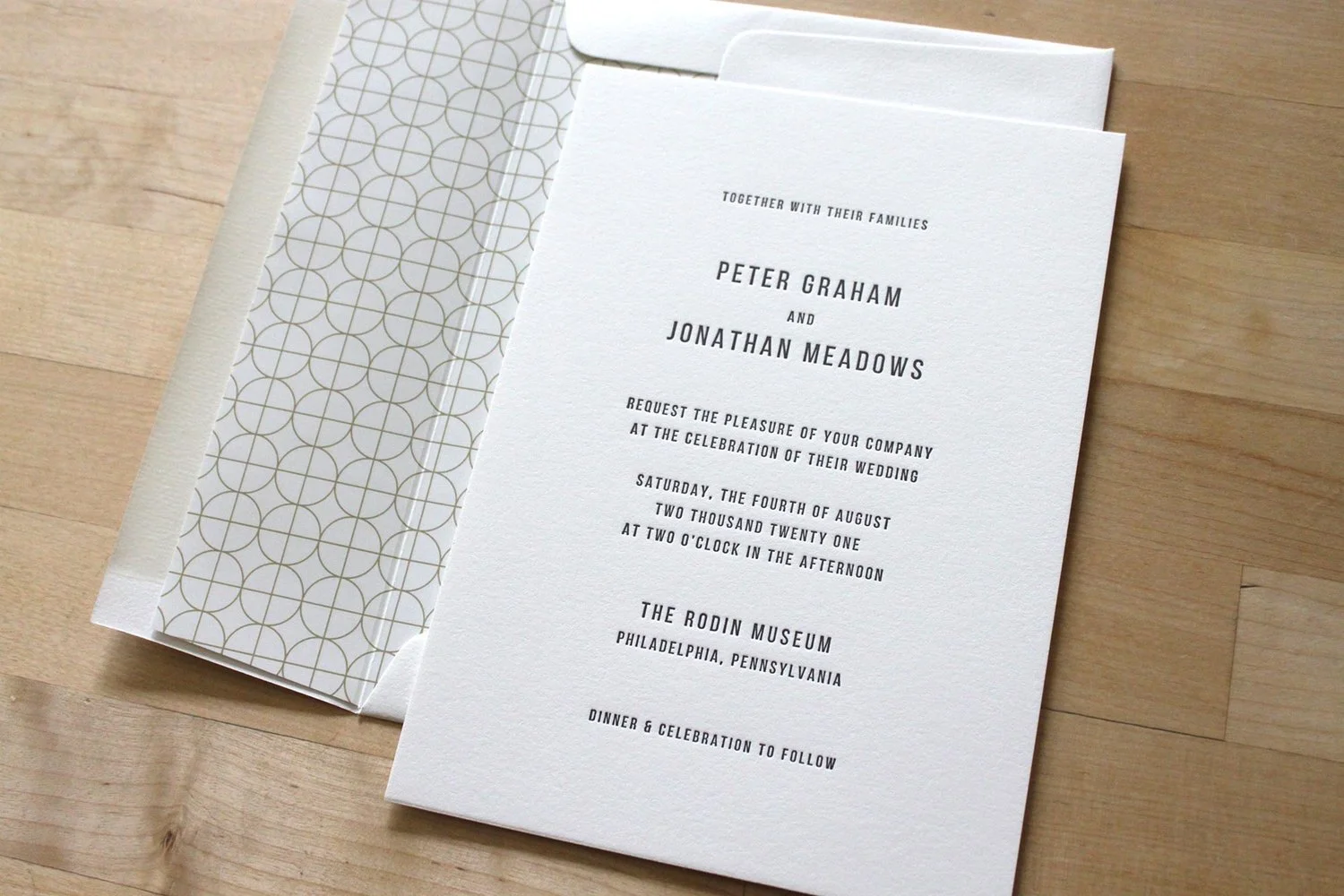

You’ve probably felt it. That specific, tactile "thump" when a heavy cardstock envelope hits your floor mat. It’s different from the flimsy bills or the glossy pizza coupons. When you pull out a suite of custom letterpress wedding invitations, your fingers immediately find the indentations. It’s a physical deboss that tells your brain, “Hey, this event actually matters.” Honestly, in an era where we RSVP to life-changing events via a "Going" button on a screen, there’s something almost rebellious about 15th-century technology. Gutenberg would recognize the machines being used in boutique shops across Brooklyn and Portland today. We’re talking about massive, cast-iron Heidelbergs and Chandlers & Price presses that weigh more than a small SUV. These machines don't just print; they smash ink into cotton.

The Physicality of the Deep Impression

Let’s get one thing straight: letterpress wasn't always supposed to look like this.

Back in the day, a "salty" or deep impression was actually considered the sign of a bad printer. It meant you were wearing out your type. But today? That deep pillowy texture is exactly what you’re paying for. Most high-end stations use 100% cotton paper—brands like Crane & Co. or Reich Paper are the gold standards here—because cotton fibers are soft. They take the hit of the metal or photopolymer plate without tearing.

If you try to letterpress on standard wood-pulp paper, it just looks flat. Or worse, it cracks.

You’ve got to think about the "show-through" too. If you want that ultra-deep crunch on both sides of a double-sided card, you’re going to need 220lb (600gsm) paper. It’s basically a coaster at that point. Thick. Substantial. It feels like an heirloom before the wedding even happens.

Why the Cost Makes People Cringe (And Why It’s Fair)

I’ve seen couples go pale when they see a quote for 100 sets of letterpress invites. It’s often double or triple the price of digital flat printing.

Why?

Because it’s a labor-intensive nightmare for the printer.

👉 See also: Birthday Outfit Ideas for Women: What Actually Works (and What to Skip)

Unlike your home inkjet that sprays colors all at once, a letterpress is a "one pass per color" deal. If you want a dusty rose header and forest green text, that invitation has to go through the press twice. The printer has to mix the ink by hand (usually using the Pantone Matching System), wash the press entirely, set up the second plate, and align it perfectly—a process called registration. If the alignment is off by even half a millimeter, the whole batch looks like a 3D movie without the glasses.

Then there’s the plate cost. Every unique design requires a custom-etched photopolymer plate. You aren't just paying for paper; you're paying for a physical tool manufactured just for your names.

The Realities of Ink and Paper

- Transparent Inks: Letterpress ink is naturally a bit translucent. If you try to print white ink on black paper, the black paper "drinks" the ink and it looks like a faint, ghostly grey. For that crisp white-on-dark look, you usually need foil stamping, which is a different beast entirely involving heat and metallic films.

- The "Flop" Factor: Not every design works. Super thin lines can disappear or "fill in" with ink if the pressure isn't dialed in perfectly. Expert designers like those at Bella Figura or Dauphine Press often thicken their hairlines specifically to survive the press.

- Hand-Mixing: Every batch of ink is mixed by eye and a scale. There might be a 2% variation between a sample you saw online and the invite in your hand. That’s not a bug; it’s a feature of artisanal work.

Custom Letterpress Wedding Invitations: Navigating the Design Process

Don't just hand a printer a Canva file and hope for the best. Letterpress demands "vector" art. These are mathematical lines created in programs like Adobe Illustrator. If you send a grainy .JPG, the plate-maker literally can't create the sharp edges needed for that crisp "bite" into the paper.

You also have to consider the "breathing room." Letterpress looks best when there is plenty of white space. Cramming 400 words of tiny text onto a 5x7 card makes the paper look busy and cluttered. It also makes it harder for the printer to keep the ink coverage even.

Think about the edges, too. Edge painting—where the printer hand-sponges or sprays a pop of color onto the sides of the stacked cards—only works if the paper is thick enough. If you’re doing a 110lb single-ply card, edge painting is almost invisible. Go for the 220lb double-ply if you want that neon or gold flash on the side.

Common Misconceptions That Waste Money

People think "more is better," but with letterpress, "less is luxury."

A common mistake is trying to do a full-color photo of the couple using letterpress. You can't. It’s not a photo printer. If you want a photo, you have to do a "digital hybrid" where the photo is flat-printed first, and then the text is letterpressed over or around it.

Another one? Thinking "blind hit" is cheaper. A blind hit is when you press the plate into the paper with no ink. It creates a beautiful, subtle shadow effect. Since it still requires a custom plate and a full press setup, most shops charge the same price as a one-color print.

The Sustainability Angle

Kinda surprisingly, letterpress is often the "greener" choice if you do it right. Many of the top studios use soy-based inks rather than oil-based ones. Since the paper is almost always 100% cotton, it’s actually a byproduct of the textile industry—linters that would otherwise be thrown away.

Plus, people don't throw these away.

Think about it. Most wedding invites end up in the trash a week after the wedding. But a heavy, letterpressed piece of art? People keep those. They end up in frames or tucked into books. You’re creating a permanent record.

Actionable Steps for the Budget-Conscious Couple

If you’re dying for that texture but the $2,000 price tag is ruining your life, there are ways to pivot without losing the vibe.

- The One-Color Strategy: Stick to a single ink color. Navy or Black on cream paper is timeless and significantly cheaper than adding a second "accent" color.

- The Hybrid Approach: Letterpress your main invitation (the thing people might save), and do "flat" digital printing for the RSVP cards and detail inserts. Nobody needs a letterpressed map of the local Marriott.

- Small Batch Printing: Some Etsy-based printers use smaller tabletop presses and can offer lower minimums. Just check their "registration" (alignment) photos closely.

- Standard Sizes: Avoid square invitations. They look cool, but the USPS charges extra for non-machinable mail, and the envelopes are harder to source. Stick to the classic A7 (5.25 x 7.25) size.

Choosing a Vendor

When you're looking for a printer, ask them what presses they use. If they say "Heidelberg Windmill," you're in good hands—those are the workhorses of the industry. Ask for a sample pack. You cannot judge letterpress through a screen. You need to feel the weight of the paper and see how the light hits the indentations.

Look for "bruising" on the back of the samples. A master printer manages to get a deep hit on the front without making the back of the card look like a Braille map. It's a delicate balance of pressure, ink tackiness, and paper humidity.

Basically, custom letterpress wedding invitations are a flex. They tell your guests that this isn't just another party—it's a milestone. It’s tactile, it’s historical, and it’s undeniably beautiful.

Next Steps for Your Invitations:

- Order a physical sample kit: This is non-negotiable. Look for 110lb vs 220lb cotton samples to decide if you want the extra thickness.

- Finalize your word count: Minimize the text on your main invite to allow the letterpress "white space" to shine.

- Check your timeline: Letterpress takes time. Between design, plate making, and the actual press run, you need to start this process at least 4 to 5 months before your wedding date.