Look around any gym, office, or local park. People are carrying water everywhere. It’s basically an appendage at this point. If you’re running a business and trying to get your name out there, you’ve probably looked at a dozen different ways to do it. You’ve seen the social media ads that disappear in a second. You’ve seen the flyers that end up in the trash before they're even read. But custom plastic water bottles with logo are different. They stick around. They actually do something useful.

I’ve spent years watching how promotional products move through the real world. Honestly, most of it is junk. Cheap pens that leak? Straight to the bin. Flimsy tote bags? Maybe they hold groceries once. But a decent water bottle? That stays on a desk for six months. It goes to the yoga studio. It sits in a car cup holder during a morning commute. It’s constant, subtle exposure.

It isn't just about slapping a sticker on a bottle. It’s about the psychology of utility. When you give someone something they actually need—like hydration—you aren't just "marketing" to them. You're helping them. That creates a weirdly strong positive association with your brand that a Facebook ad just can't touch.

The weird physics of why plastic actually beats metal sometimes

Everyone is obsessed with stainless steel right now. I get it. They look fancy. But let's be real: they’re heavy and expensive. If you’re hosting a 5K run or a massive trade show, you aren't handing out $20 vacuum-insulated flasks to 5,000 people unless you have a literal mountain of cash to burn.

Plastic is the workhorse of the industry.

When we talk about custom plastic water bottles with logo, we’re usually talking about BPA-free Eastman Tritan or high-density polyethylene (HDPE). Tritan is that stuff that looks like glass but you can drop it on concrete and it just bounces. It’s tough. It’s clear. It doesn't hold onto that weird "old gym bag" smell that cheaper plastics do.

The real magic of plastic is the weight. If you’re a hiker or someone who’s constantly on the move, every ounce matters. A lightweight plastic bottle is often preferred over a heavy metal one. Plus, they’re translucent. You can actually see how much water you have left, which is a small but surprisingly important detail for people trying to hit their daily hydration goals.

What most people get wrong about the design

You’ve seen the bad ones. A tiny, pixelated logo shoved into the middle of a neon green bottle. It looks cheap. It feels like an afterthought.

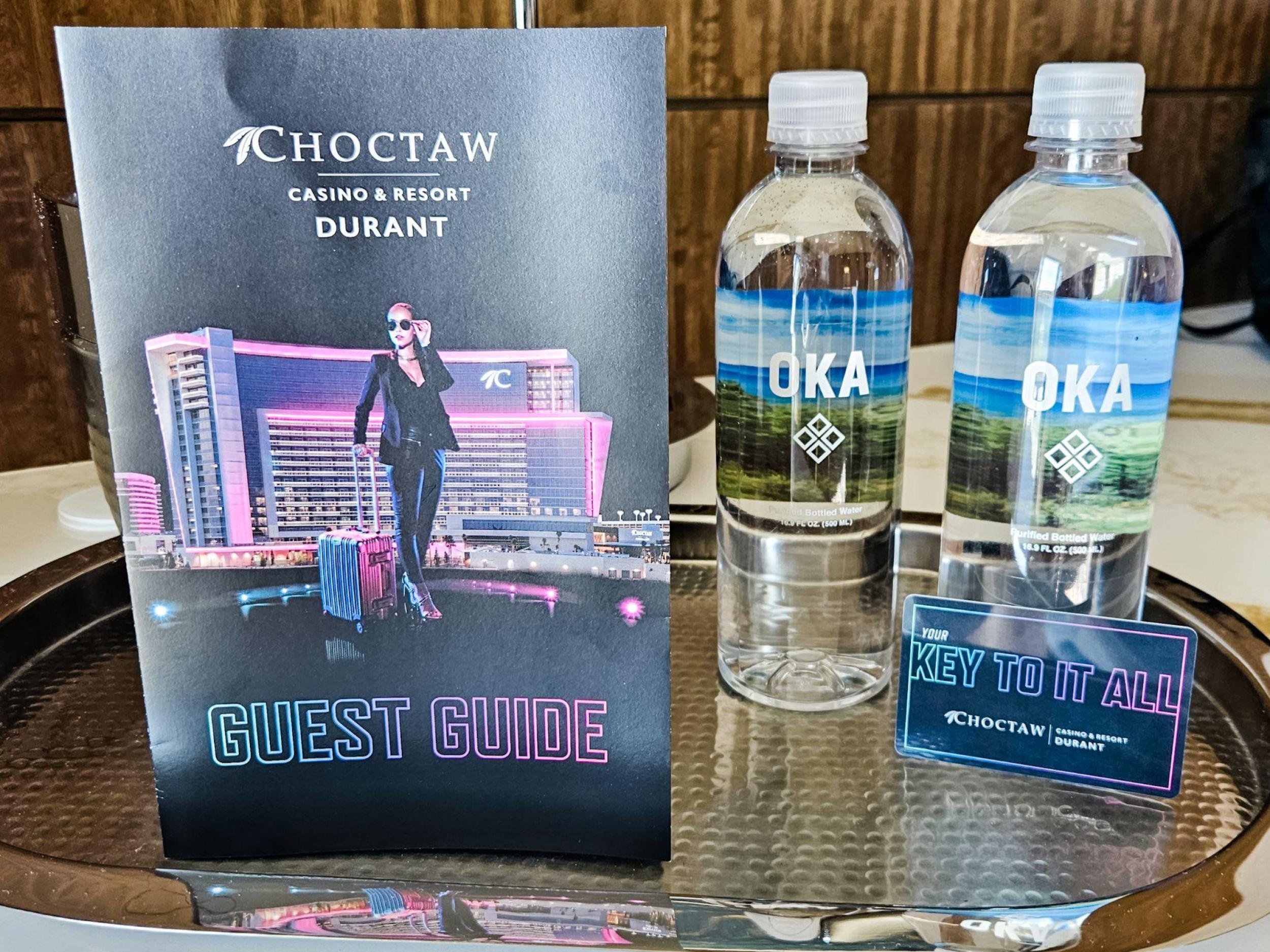

If you want people to actually use your branded gear, you have to think like a designer, not a billboard salesman. Think about "retail-inspired" design. Brands like CamelBak and Nalgene have set a high bar for what a water bottle should look like. If your custom bottle looks like something someone would actually buy at an outdoor gear shop, they’re going to keep it.

The "Sip" Test

Think about the lid. Seriously.

- Is it a screw-top?

- Does it have a straw?

- Is there a flip-bit that’s going to snap off after three uses?

If the lid is annoying, the bottle is dead. I’ve seen companies spend thousands on beautiful bottles only to go cheap on the lids. The result? Leaks in laptop bags. Total brand disaster. If your logo is on a bottle that ruined someone's MacBook, you haven't done marketing; you’ve made an enemy.

Sustainability isn't just a buzzword anymore

Let’s address the elephant in the room: plastic. We’re all trying to use less of it. So, how do you justify giving away plastic bottles?

The math is actually pretty simple. The goal of a custom plastic water bottle with logo is to replace single-use bottled water. According to data from the Container Recycling Institute, Americans throw away about 60 million plastic water bottles every single day. If your branded bottle gets used 50 times, you’ve kept 50 single-use bottles out of a landfill.

Most high-quality plastic bottles today are made from recycled content (rPET) or are designed to be 100% recyclable at the end of their life. When you choose a durable, reusable option, you’re actually promoting a more sustainable lifestyle. You’re telling your customers, "Hey, stop buying those crinkly disposables and use this instead."

The cost-per-impression is actually insane

If you buy a high-quality plastic bottle in bulk, you might be paying $3 to $7 per unit depending on the material and the complexity of the print.

🔗 Read more: Schwab Muni Bond ETF: Why Most Investors Overlook This Tax Play

Now, let’s look at the lifespan. An ASI (Advertising Specialty Institute) study found that the average person keeps a promotional drinkware item for about 12 months. During that year, that bottle generates roughly 1,400 impressions.

Do the math.

You’re paying a fraction of a cent per "view." Compare that to a Google Search ad where you might pay $2.00 just for one person to click a link and leave your site five seconds later. The bottle stays. It lives in their kitchen. It goes to their kid's soccer game. It’s a physical presence in their life.

Navigating the "BPA-Free" landscape

Back in the mid-2000s, everyone panicked about Bisphenol A (BPA). For good reason. It was linked to all sorts of health issues. Today, finding a bottle that isn't BPA-free is actually kind of hard, but you still need to be careful.

When you’re sourcing custom plastic water bottles with logo, look for the "BPA-Free" stamp on the bottom. But go a step further. Ask for "BPS-free" as well. Some manufacturers replaced BPA with BPS (Bisphenol S), which some researchers at places like the University of Missouri suggest might be just as problematic.

If you want to be the hero of the trade show, go for Tritan plastic. It’s the gold standard. It’s shatter-resistant, dishwasher safe, and it doesn't leach anything into the water. It feels "premium" in the hand. That tactile feel matters. If the plastic feels soft or greasy, people won't trust it.

Distribution: Where most businesses fail

You’ve ordered 500 bottles. They’re sitting in your garage or office storage room. Now what?

Don't just leave them in a box. And definitely don't just hand them to everyone who walks by like you’re giving out flyers. Scarcity creates value.

- The Onboarding Gift: Give a bottle to every new client or employee. It says "Welcome to the team" better than a PDF ever could.

- The Milestone Reward: "Thanks for being with us for a year."

- The Event Exclusive: Make them a "limited edition" for a specific conference or seminar.

I once saw a tech company do a "color drop." They released 50 blue bottles, then 50 red ones, then 50 matte black ones. People were actually trading them. It turned a simple piece of plastic into a collectible. That's how you win at this.

Screen printing vs. Full-color wrap

You have choices when it comes to the actual branding.

Screen printing is the classic. It’s durable and cheap for large runs. You get crisp, solid colors. But you’re usually limited to one or two spots on the bottle.

If you really want to stand out, look at 360-degree digital printing. This allows for full-color photography or complex patterns that wrap around the entire circumference of the bottle. It’s more expensive, sure. But it makes the bottle look like a piece of art. Imagine a mountain range wrapping around the base, or a vibrant abstract pattern that reflects your brand's energy.

The "Leaky Bottle" Horror Story (and how to avoid it)

I knew a guy who ordered 2,000 cheap sports bottles for a marathon. They were those soft, "squeeze" style bottles. He saved about $0.50 per unit by going with a budget supplier.

Halfway through the race, the lids started popping off. Runners were getting soaked. The logos were literally peeling off onto people's hands because the ink hadn't cured properly on that specific type of LDPE plastic.

The lesson? Get a sample. Always.

Fill it with water. Put it in your bag. Shake it. Drop it. If you wouldn't use it yourself, don't give it to a customer. Your brand's reputation is literally held together by the threading on that lid.

Technical Specs: Knowing your plastics

It helps to know what you’re buying so you don't sound like a newbie when talking to suppliers.

PET (Polyethylene Terephthalate): This is what soda bottles are made of. For reusables, it’s usually thicker. It’s clear and cheap, but not great for hot liquids.

PP (Polypropylene): This is that slightly cloudy, tougher plastic. It’s heat-resistant. If you want a bottle that can handle a hot dishwasher or even hot tea, PP is a solid middle-ground.

Tritan: Like I said, this is the king. It’s a copolyester. It has the clarity of glass but the weight of plastic. It’s almost indestructible. If you want to impress high-value clients, this is the only way to go.

Real-world impact: A case study in miniature

A small gym in Austin started giving out custom plastic water bottles with logo to anyone who signed up for a 12-month membership. They spent about $5 a bottle.

Within three months, they noticed something weird. People were bringing those bottles to work. Coworkers would ask about the gym. The "referral" rate spiked by 15% without the gym owner spending a single extra dollar on digital ads.

That’s the power of a physical object. It’s a conversation starter. It’s "social proof" that someone likes your business enough to carry your logo around in public.

Actionable Steps for your first order

If you’re ready to pull the trigger, don't just search for the cheapest price on the internet.

First, define your audience. Are they office workers who want something sleek for their desk, or are they outdoor types who need a loop on the lid for a carabiner? This dictates the bottle shape.

Second, simplify your logo. A complex logo with tiny text won't print well on a curved surface. Bold, clean lines work best. If your logo is vertical, consider a "wrap" print so it’s readable from any angle.

Third, choose your color wisely. Don't just match your brand color. Think about the "lifestyle" of the user. A bright orange bottle might be cool for a brand, but will someone take it to a professional boardroom meeting? Neutral colors like charcoal, navy, or clear often get used more frequently because they "fit in" everywhere.

Fourth, check the lead times. Custom manufacturing usually takes 2-4 weeks. If you have an event on Friday and it's currently Monday, you're looking at "rush shipping" fees that will make your eyes water. Plan ahead.

Finally, think about the shipping. Water bottles are light, but they’re bulky. They take up a lot of space in a truck. Shipping costs can sometimes be 20% of your total order. Always ask for an "all-in" quote that includes freight, setup fees, and taxes. No surprises.

👉 See also: When Did the Federal Reserve Start: The Real Story Behind America’s Most Powerful Bank

Investing in quality custom plastic water bottles with logo isn't about the plastic; it’s about the presence. It’s a way to stay in your customer's hand, literally, every single day. If you do it right, you aren't just giving away a gift—you're becoming part of their daily routine.

Start by ordering three different samples from three different manufacturers. Use them for a week. See which one ends up being the one you reach for in the morning. That’s the one your customers will want, too.